There is an intertwined relation between PCB assembly and circuit board manufacturing. In this light, we will be tackling PCB assembly in line with circuit board manufacturing. Prior to PCB assembly, several preparatory measures are being considered for the circuit board manufacturers to make the proper assessment of the functionality of the PCB design and have a DFM check.

There are companies that specialize in manufacturability check or commonly called the DFM check, which is geared to assess the PCB file for any possible issues that will eventually affect the PCB functionality or manufacturability.

The manufacturability checks or DFM looks at the specifications design of a PCB. It is a thorough check on redundant, missing, or features that may be the potential to cause malfunction. These concerns have an adverse effect on the functionality of the final project.

Common problems noted in the PCB design flaw are having a short spacing between the components that may potentially cause some malfunctioning. Identifying these issues is being made prior to the circuit board manufacturing. The DFM further checks the possible manufacturing cost and the tendency to cut down any unnecessary costs. Reducing the cost of manufacturing can possibly be done by cutting down on the number of scrapped boards.

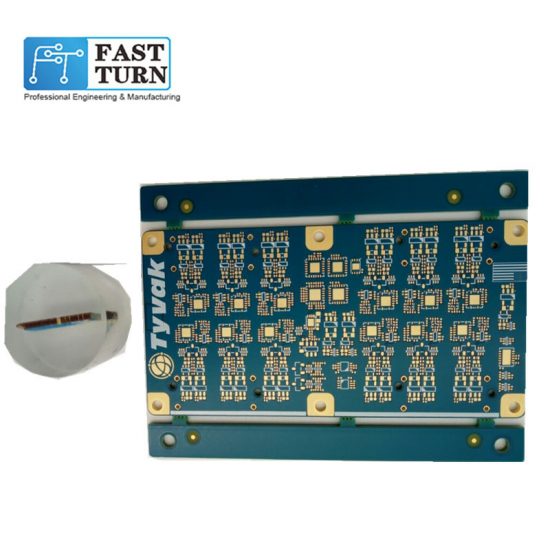

Fast Turn PCB is considered a trustworthy company that is geared towards providing quality PCB and services. It has a PCB quick turn shop, PCB production shop, and PCB assembly shop. Primarily it is based in China and had been operating for almost 12 years. Its very core is “quality,” and it ensures that appropriate and intensified check has been done in PCB prior to the manufacturing process. In PCB manufacture, Fast Turn PCB is known for making multilayer 4-50 layer, HDI blind, and rigid-flex.

It is also in Fast Turn PCB where you can find ShengYi A1000-2M, ITEQIT1804 AS WELL AS tu768, and KB FR4. There Is also the availability of Rogers4000s, 3000s, 5880, VT-901, and FTG-8000 series.

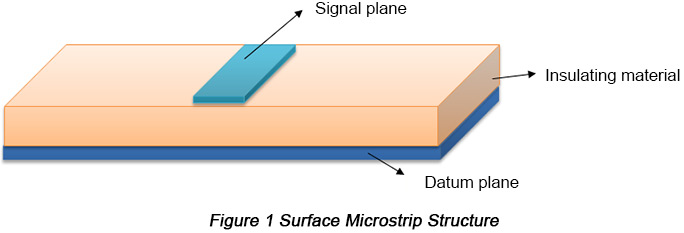

The manufacturing circuit board could either be single-sided with one copper layer or having two layers of copper that are outer and inner alternating layers of a substrate which is called a multi-layer. PCB with a multi-layer has a higher component density for the circuit traces in the inner layers can take the surface space between the components.

The growing demand for a multi-layer PCB may be attributed to the current trend of adopting a surface mount technology. There may be some drawbacks in using a multilayer PCB, such as difficulty in removing components, especially during the needed repair.

Whatever you may need, may it be a multilayer or a single layer, you can always be assured to get the best from Fast Turn PCB. Its Research and Development Team does not settle for something that is less and always innovating in order to meet and may even surpass the expectations of their clientele.

When looking for the most reliable circuit board manufacturing, do not turn your head to other companies when you can have your eyes already set for the best, which is the Fast Turn PCB. Your choice of company will spell a great difference to the kind of PCB that you will have now and in your future needs.