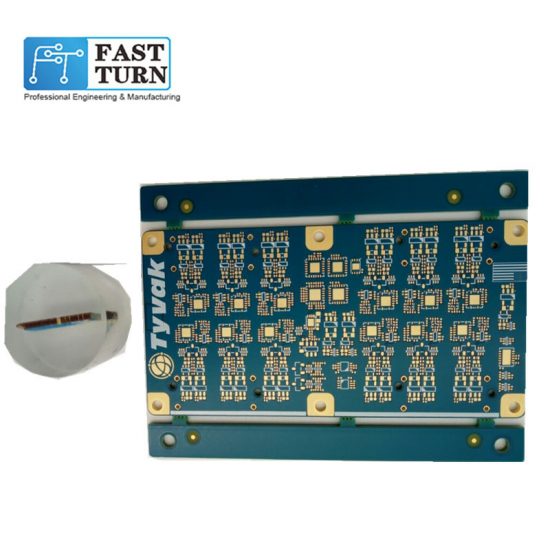

In the bustling world of electronics, the demand for miniaturized and versatile components continues to rise. An ingenious innovation stands at the heart of this modern revolution, the Flexible Printed Circuit Board or Flex PCB. Characterized by its thin profile and malleability, this versatile technology has taken the electronics industry by storm, proving integral in various applications, from medical devices to consumer electronics and aerospace systems.

Understanding Flex PCBs: Beyond the Basics

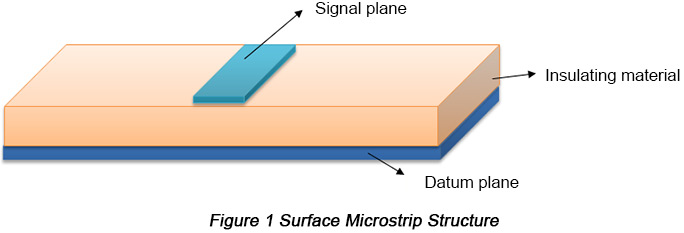

In simple terms, a Flex PCB is a design of printed circuits and components that uses a flexible material, with or without an overlay, to create a patterned arrangement. The flexibility of these PCBs allows them to bend, twist, and fold, adapting to the design constraints of the device they inhabit. This is a dramatic departure from traditional rigid PCBs, whose inflexibility often necessitated design compromises.

Material Composition and Manufacturing Process of Flex PCBs

The primary material used in manufacturing Flex PCBs is polyimide, a high-temperature resistant polymer that can withstand the soldering process while maintaining its flexible properties. It also offers excellent electrical properties, making it an ideal material for flexible circuit board construction.

The process of manufacturing Flex PCBs involves several intricate steps:

- Creating a circuit pattern on the polyimide sheet is usually achieved using photolithography.

- The excess copper is etched away, leaving behind the desired circuit pattern. The circuits are then laminated with a layer of polyimide to protect them. Following this, drilling and plating processes are carried out to create through-holes for component attachment.

- The components are soldered onto the board and ready for installation.

Advantages of Flex PCBs

The rising popularity of Flex PCBs is no coincidence. Their unique attributes offer many advantages that set them apart from their rigid counterparts.

Space and Weight Savings

Flex PCBs are incredibly thin and lightweight, leading to significant savings in both space and weight. This is especially beneficial in modern electronics, where device miniaturization is a top priority. Furthermore, the flexibility of these PCBs allows for creative designs that maximize component density and eliminate the need for connectors and wiring harnesses.

Durability and Reliability

Flex PCBs are also more durable than traditional PCBs. They resist vibrations and shock, reducing the chances of mechanical failures. The fewer interconnections also mean fewer potential failure points, improving reliability.

Heat Dissipation

Due to their thin profile, Flex PCBs are excellent at dissipating heat. This ability is critical in high-power applications where heat management is a significant concern.

Applications of Flex PCBs

Thanks to their unique attributes, Flex PCBs have entered various applications.

Consumer Electronics

Flex PCBs are widely used in devices such as smartphones, tablets, laptops, and wearables in consumer electronics. They enable the creation of slim, lightweight, and flexible devices that have become the norm in today’s tech-intensive world.

Medical Devices

In the medical field, Flex PCBs are critical in devices like hearing aids, pacemakers, and implantable defibrillators. They offer the necessary flexibility and miniaturization required for these life-saving devices.

Aerospace and Military Applications

Flex PCBs also play a vital role in aerospace and military applications. Their ability to withstand extreme conditions and resist vibrations makes them ideal for aircraft, satellites, and military-grade equipment.

Conclusion: Embracing the Flex PCB Revolution

The advent of Flex PCBs has undoubtedly revolutionized the world of electronics. Their unique attributes, such as flexibility, lightweight, durability, and excellent heat dissipation, offer advantages that traditional rigid PCBs cannot match. From enabling the creation of sleek and compact consumer electronics to facilitating the functioning of critical medical devices and aerospace systems, Flex PCBs are shaping the future of electronics.

As we look ahead, the demand for Flex PCBs is only expected to rise as they push the boundaries of design and functionality. Their ever-expanding potential underscores the importance of understanding and embracing this versatile technology. In electronics, the Flex PCB revolution is well underway, promising exciting possibilities for the future.