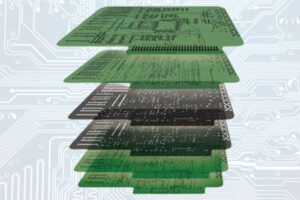

The selection of PCB substrate material for medical equipment is crucial, and it needs to meet requirements such as reliability, stability, electrical and mechanical properties. Common materials include FR-4, aluminum substrate, flexible substrate, and fiberglass board. When making a selection, consideration should be given to performance requirements, cost budgeting, manufacturing processes, and regulatory compliance.

1、 Requirements for Material of Medical PCB Substrates

Medical devices have much higher requirements for PCB substrates than general electronic devices.

Firstly, medical PCBs need to have extremely high reliability and stability to ensure stable performance and no malfunctions during long-term use.

Secondly, the substrate material of medical PCBs must have excellent electrical and mechanical properties to meet the requirements of high-precision and high-frequency operation.

In addition, considering that medical equipment may need to work in harsh environments such as high temperature and humidity, the substrate material should also have good heat and corrosion resistance.

2、 Common medical PCB substrate materials

1. FR-4 substrate: FR-4 is a composite material made by pressing epoxy resin and fiberglass cloth, which has good mechanical strength, electrical performance, and heat resistance. In medical equipment, FR-4 substrate is widely used due to its stable performance and moderate cost.

2. Aluminum substrate: Aluminum substrate is known for its excellent heat dissipation performance, especially suitable for medical equipment that requires efficient heat dissipation, such as ultrasound diagnostic devices. Aluminum substrates not only effectively transfer heat from the circuit board to the heat sink, but also have good mechanical strength and electromagnetic shielding effect.

3. Flexible substrate (FPC board): For medical devices that require bending or curling, such as wearable health monitoring devices, flexible substrates are an ideal choice. It has the characteristics of high wiring density, light weight, thin thickness, and good bending performance.

4. Fiberglass board: Fiberglass board is mainly made of fiberglass, which has high mechanical strength and heat resistance, and is suitable for medical applications at high temperatures and frequencies.

3、 Factors to consider when selecting substrate materials

When selecting the substrate material for medical PCBs, the following factors need to be comprehensively considered:

Performance requirements: Select substrate materials with corresponding characteristics based on the specific performance requirements of medical equipment. For example, for devices operating at high frequencies, a substrate with low loss and good signal transmission performance should be selected.

Cost budget: While meeting performance requirements, cost is also an important consideration factor. The prices of substrates made of different materials vary greatly, and a reasonable selection should be made based on the market positioning and budget constraints of the equipment.

Manufacturing process: The selection of substrate material also needs to consider the feasibility of the manufacturing process. Certain substrates made of special materials may require specific processing equipment and processes, which can increase manufacturing costs and time.

Safety and compliance: Medical devices must comply with relevant regulations and standards, such as FDA RoHS et al. The selection of substrate material should ensure that it does not contain harmful substances and meets the safety requirements of the medical industry.