According to media information, There are more than 50 semiconductor companies in Malaysia, most of which are multinational companies. Many multinational companies, including well-known Italian-French semiconductor, Ti, Intel, Renesas and Rimoonlight, have a presence in Malaysia. Most of these companies have assembly testing and wafer manufacturing lines in Malaysia.

Malaysia is also a manufacturing hub for Japanese and Taiwan-based passive components companies, including Murata, Wintek, Toshiba, Nishihua, Huaxin technology and Wang Quan, which all have production capacity in Malaysia.

Infineon, ON Semi, ST, NXP and other index integrated component plants (IDM) are in production locally, focusing ON power semiconductors such as MOSFET. At present, the supply of MOSFET is deteriorating and local integrated component plants in Malaysia are struggling to fill new orders due to lack of work, which may reduce MOSFET lead times again.

Secondly, Malaysia is also one of the major sealing and testing centers in the world. Southeast Asia is estimated to account for 27% of the global container testing market, with Malaysia accounting for half. Malaysia has riyueyue, Tongfu Micro electric, Huatian Technology, Suzhou Gutai technology and other sealing test factories.

Some industry insiders believe that at present, some semiconductor manufacturers have suspended taking orders, and the impact of a lack of labor has become significant. If the labor shortage continues, it could lead to a new round of semiconductor shortages.

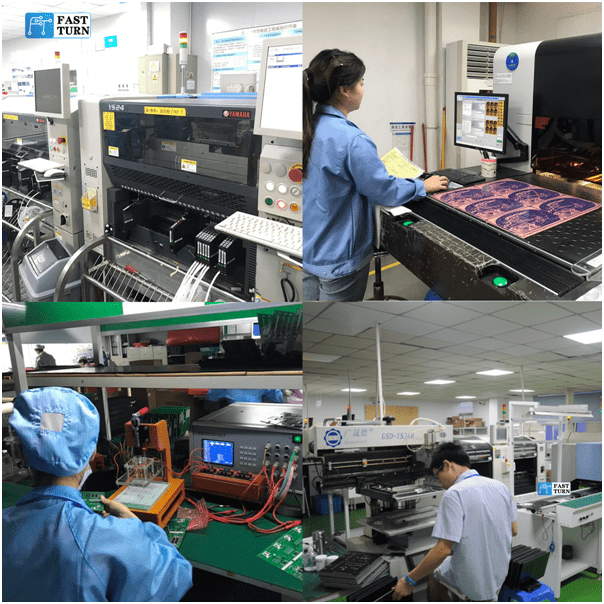

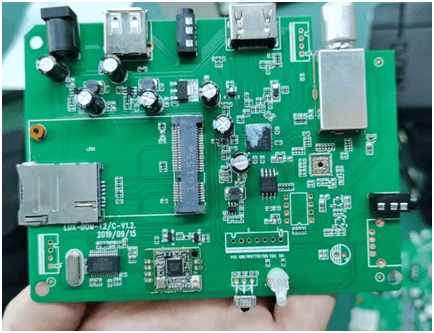

Founded in 2015, The company takes PCB sample manufacturing as the entrance, and has the ability of fast delivery of high-end samples and small and medium-sized batches. Through the whole value chain services such as PCB manufacturing, BOM purchasing and PCB assembly, we provide customers with vertically integrated one-stop solutions for their products. We continue to contribute to the continuous innovation and development of China’s electronic technology, in order to build a first-class electronic product design and manufacturing outsourcing service provider. Pursue the material and spiritual happiness of all staff and make contributions to the progress and development of mankind and society.

We offer professional design solutions covering all aspects of PCB and PCBA layout, including the following board technologies.

Include:

1.PCB design: free laminated design and impedance calculation.

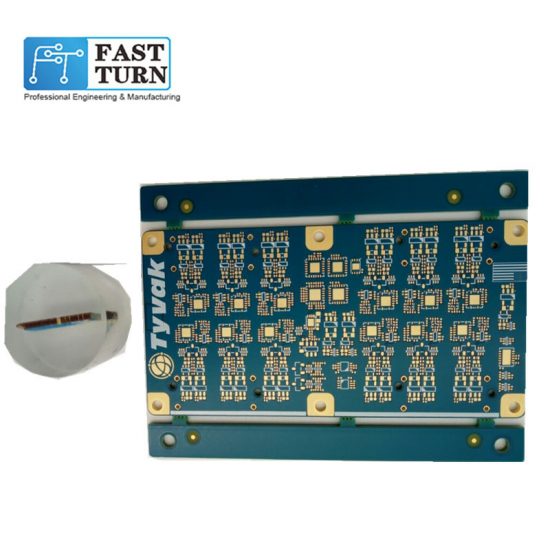

2.PCB manufacturing :PCB board making capacity of 1-48 layers, blind hole, copper thickness up to 12 ounces

3. Component purchase :BOM purchase within 3 days

4.PCB assembly: urgent sample and batch assembly processing, only 1-3 days

5. Functional testing

6. Electronic assembly global logistics

7. Single, double-sided, multi-layer board

8. Rigid circuits, flexible circuits and rigid-flexible circuits.