The heart of every electronic device we use today lies a Printed Circuit Board (PCB). These essential components are the foundational building blocks that power our digital world, from smartphones and computers to life-saving medical equipment and cutting-edge aerospace technology. The intricacy of the process and the precision required in the production of PCBs underline the significance of PCB manufacturers. This article delves deep into the fascinating realm of printed circuit board manufacturers, offering a detailed overview of the industry, the key players, and the technological advancements shaping the future of PCB production.

The Role of PCB Manufacturers

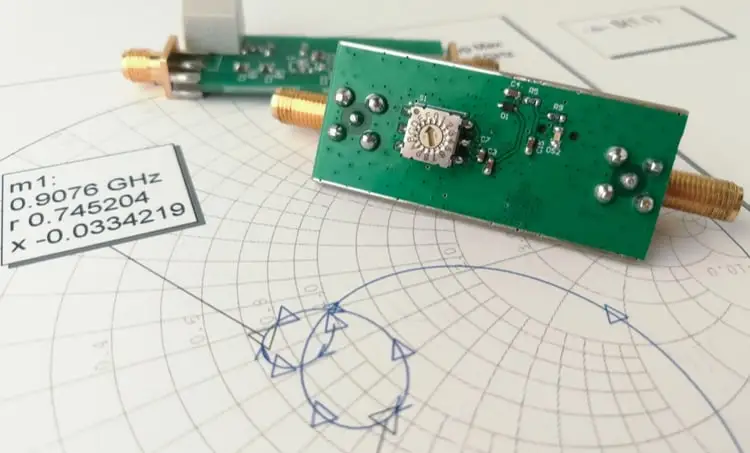

Printed Circuit Board manufacturers are the core players in the electronics sector, responsible for transforming designs into functional PCBs. Through a complex process of etching, drilling, lamination, and testing, these manufacturers breathe life into the intricate designs engineers conceptualize. They not only produce but also refine methods, suggest improvements, and ensure the quality and performance of the finished product.

A Dynamic Industry Landscape

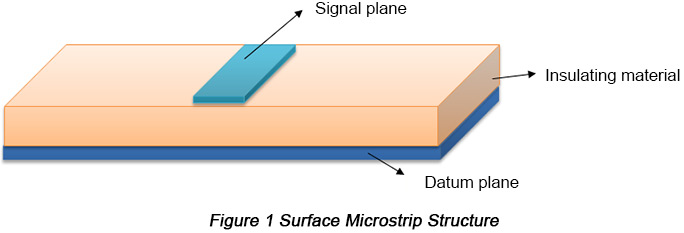

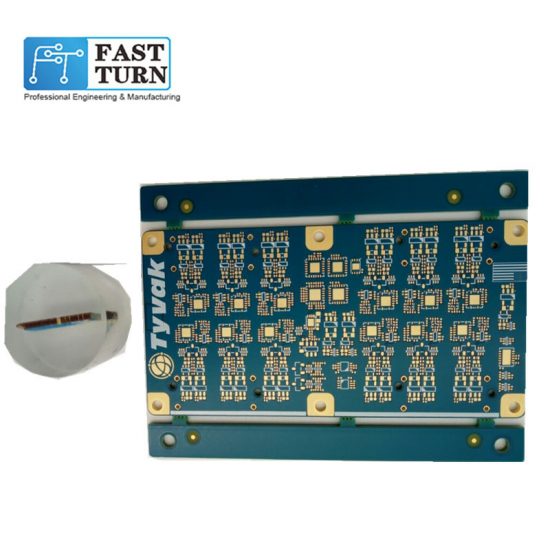

PCB manufacturing is a dynamic industry with a constantly evolving landscape. Driven by continuous technological advancements and the rising demand for electronic products, manufacturers must keep pace with changing needs and trends. Over the years, the industry has seen the entrance of new players and witnessed a shift towards high-density interconnect (HDI) PCBs, flex and rigid-flex PCBs, and the incorporation of more contemporary materials, such as ceramic and polyimide.

Key Players in the PCB Manufacturing World

The PCB manufacturing industry has numerous players, each bringing its unique blend of expertise, experience, and technology. Certain names stand out for their consistent performance, quality, and innovation. Companies like Zhen Ding Technology, TTM Technologies, and Ibiden Co., Ltd. are recognized for their commitment to technological advancement and quality assurance in PCB production.

Technological Advances and the Future of PCB Production

The future of PCB manufacturing lies in technological advancement and automation. Advances in AI, Machine Learning, and robotics are revolutionizing how PCBs are produced. Automated Optical Inspection (AOI), a technology that uses a high-definition camera to inspect PCBs for defects, has become an industry standard. Other technologies, such as X-ray and automated solder paste inspection (SPI), have also become integral parts of the PCB manufacturing process. 3D printing technology or additive manufacturing is another promising avenue, opening up possibilities for rapid prototyping and small-batch production of PCBs.

The growing emphasis on sustainable manufacturing practices has also prompted PCB manufacturers to explore eco-friendly materials and production processes. Adopting lead-free solder and reducing hazardous substances in PCB manufacturing are steps toward achieving this goal.

Navigating the Challenges

While PCB manufacturers drive innovation and technological progression, they face significant challenges. The demand for small yet efficient PCBs has risen with the advancement of electronic device miniaturization. This has amplified the complexity of designs and manufacturing processes. The industry faces various challenges, such as supply chain disruptions, the demand for sustainable production practices, and balancing quality with cost-efficiency.

Conclusion

Printed circuit board, manufacturers are the bedrock of the electronics industry. Their ability to convert complex designs into tangible, high-performing PCBs is critical to powering the digital world we live in today. The future of PCB manufacturing is exciting and promising, with technological advances and sustainability initiatives leading the way. Despite the industry’s challenges, the ongoing commitment to innovation, quality, and sustainability among manufacturers ensures that the industry is well-positioned to meet the evolving needs of the electronics world.