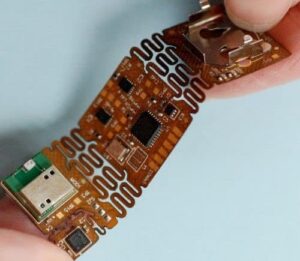

Hard and soft combination board has both the stability of hard board and soft board can be assembled in three dimensions, the development prospect is very promising. However, the production process of rigid-soft boards is complicated, and there are some key technical difficulties that are difficult to control; the following is a brief introduction to the six-layer rigid-flexible board symmetric structure.

1.The basic process of making this soft and hard board:

2. Product design features of this rigid and flexible board:

Structural symmetry

Single flex sheet

Flexible board whole board with covering film

Rigid board core thickness ≥ 0.4mm (overall board thickness ≥ 1.2mm)

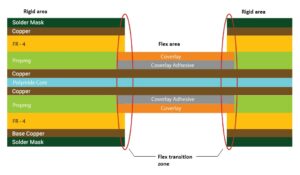

3.The following is the press-fit stack design for this soft and rigid board:

4. Difficulties in production:

4.1 Softboard section:

★Hard PCB production equipment to make soft boards, due to soft board material soft, thin, soft board over all horizontal lines need to use traction board with over, to avoid cardboard scrap.

★Press fit PI overlay film. Note that the PI cover film should be applied partially, and note the fast press parameter. The pressure should be 2.45MPa when fast pressing, and it should be flat and compacted without bubbles and voids.

4.2 Hardboard section:

★Hardboard Core’s open window and PP. hardboard use control depth milling open window, PP should use NO-FLOW PP, NO-FLOW PP can prevent overflow glue of press fit.

★Soft and rigid combination board pressed together rise and shrinkage control. Since the soft board material is less stable in terms of rise and shrinkage, priority should be given to completing the soft board, laminating PI cover film, and making the hard board part according to its rise and shrinkage coefficient.