Contact us

- Wechat&WhatsAp: +86 13829712628

- Service Hotline:+86 18011866680

- mail:sales@fastturnpcbs.com

- Sales VP:James.chen@fastturnpcbs.com

- Add:Room 2005-2012 ,No.242,

- Building A, Dongling Plaza,Xintang

- Town, Zengcheng District, Guangzhou, China

Sales Manager

About Us

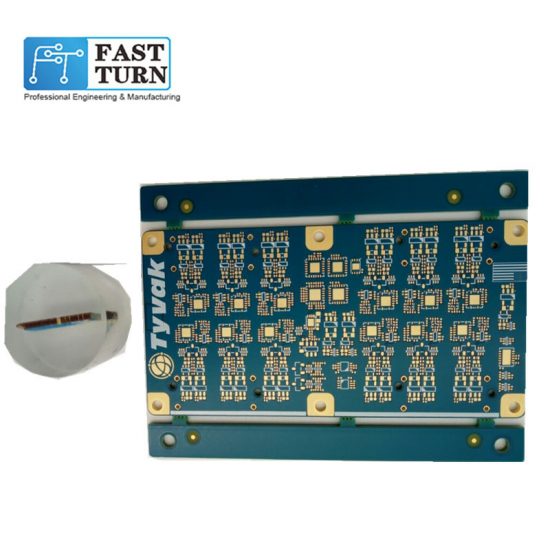

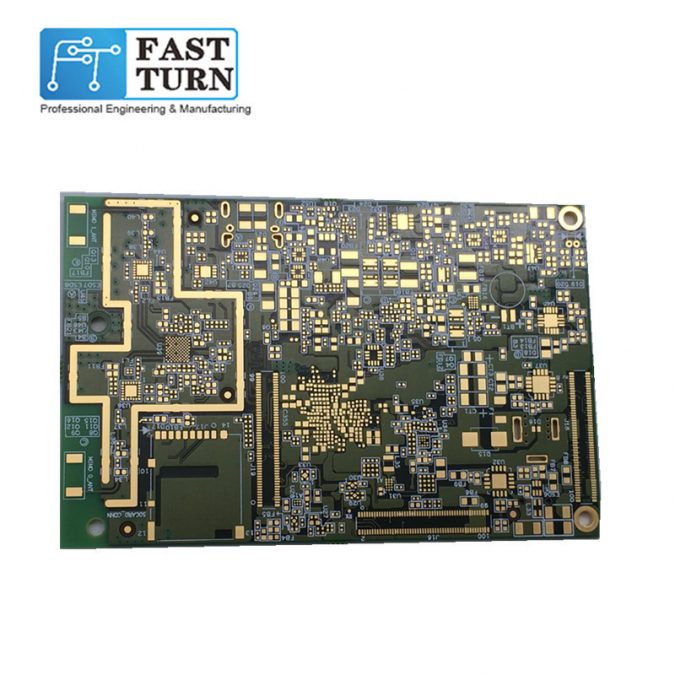

FAST TURN PCB Is Your One-stop PCB Prototype Fabricationand Assembly Service.LeadingPCB Manufacturing Company inUSA. Your only Source for HighQuality And Complex PCB FromSingle To Multilayer. Certified;UL,ISO,RoHS, IPC

CAPABILITIES

QUICK LINKS

GET IN ToUcH

- FASTTURN PCB

- +86 13829712628

- +86 18011866680

- sales@fastturnpcbs.com

- Room 503, Building A03, Ping An Technology Silicon Valley, No. 76, Chuangyu Road, Ningxi Street, Zengcheng District, Guangzhou.

Link: Chemical Samples