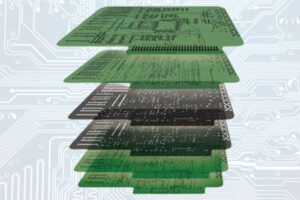

The number of layers on a PCB (printed circuit board) has a significant impact on the efficiency and quality of SMT (surface mount technology) processing. The following are specific aspects:

1. Wiring density and processing difficulty: Multilayer PCB boards have higher wiring density, which means that more precise SMT equipment and operation skills are required during SMT processing. Higher wiring density may lead to more complex circuit connections, increasing error rates and debugging time during the manufacturing process, thereby affecting processing efficiency.

2. Heat conduction and welding quality:

The thermal conductive layer in multi-layer PCB boards helps improve the thermal conductivity during the soldering process, making the soldering process more uniform and stable. Excessive thermal conductivity layer may cause heat to dissipate too quickly, thereby affecting the quality of the welded joint.

Welding quality is one of the key links in SMT processing. Poor welding may lead to decreased circuit performance, short circuits, open circuits, and other problems, affecting product quality and reliability.

3. Interlayer insulation and processing stability:

The insulation layer in multi-layer PCB boards is crucial for ensuring electrical isolation between the conductive layers. However, the presence of insulation layers may also increase the difficulty of interlayer alignment in SMT processing, thereby affecting processing stability. Inaccurate interlayer alignment may lead to issues such as component placement displacement and tilt, increasing rework rates and debugging time, and reducing processing efficiency.

4. Design flexibility and manufacturing cost:

The number of layers on a PCB board determines the design flexibility and limitations of electronic products in terms of size, functionality, and performance. PCBs with more layers can be more flexible in layout, with more freedom in the relative position of components and more complex circuit connections. However, this may also lead to an increase in manufacturing costs.

The manufacturing cost of PCBs with fewer layers is relatively low because their processing is relatively simple and the precision requirements are not high. However, the manufacturing cost of PCBs with more layers is relatively high because their processing is more complex, requiring higher precision requirements and more processing steps.

In summary, the number of PCB layers has multiple impacts on the efficiency and quality of SMT processing. When designing PCB boards, it is necessary to comprehensively consider factors such as product functionality and performance requirements, manufacturing costs, and processing efficiency to select the appropriate number of PCB board layers. Meanwhile, in the SMT processing, it is also necessary to select appropriate processing equipment and process parameters to ensure processing quality and efficiency.