The cost of SMT surface mount processing involves components, surface mount technology, soldering materials, quality control, and other costs. The calculation formula is based on factors such as component quantity, unit price, number of mounting points, and unit price. Production batch size, process requirements, equipment and labor costs also affect the cost.

1、 The basic composition of SMT surface mount processing costs

The calculation of SMT surface mount processing costs is mainly based on the following key factors:

Component cost: including the quantity and unit price of required SMD (Surface Mount Devices). The prices of different types of components (such as chips, resistors, capacitors, inductors, etc.) vary, and the more quantity there is, the higher the total cost.

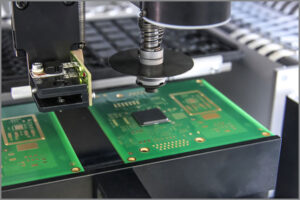

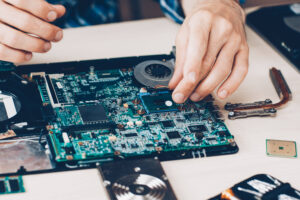

SMT process cost: This includes the depreciation cost of the SMT machine, equipment maintenance cost, and the wages of the operators. Complex circuit boards, such as high-density connections, BGA packaging, etc., require higher technology and finer operations, so the process cost may be higher.

Welding material cost: including the cost of solder wire, solder paste, cleaning agents, and other materials. The cost of different types of welding materials varies, and the amount used directly affects the total cost.

Quality control costs: involving the cost of quality testing equipment, consumables, and operator salaries. High quality requirements may increase this part of the cost.

Other expenses: such as transportation, packaging, engineering testing, and possible taxes and start-up costs.

2、 Calculation formula for SMT surface mount processing cost

Based on the above constituent factors, the calculation formula for SMT surface mount processing cost can be expressed as:

SMT surface mount processing cost=(number of SMD components x unit price of SMD components)+(number of mounting points x unit price of SMT components)+other costs+taxes

Among them, “mounting points” refer to the number of solder pads that need to be mounted on the PCB board, and different types of components may be calculated according to different points (such as resistors and capacitors usually calculated as 1 point, while complex ICs may be converted according to the number of pins). The unit price for mounting is determined based on factors such as the complexity of the mounting process and equipment performance.

Example of subdivision calculation

SMD component cost: Assuming 1000 0402 resistors are required at a unit price of 0.01 yuan per resistor, the component cost is 1000 * 0.01=10 yuan.

Installation points and cost: Assuming each resistor is calculated as 1 point, the total installation points are 1000 points, and the installation unit price is 0.015 yuan/point, then the installation cost is 1000 * 0.015=15 yuan.

Other expenses: including welding materials, quality control, transportation and packaging costs, assuming a total of 5 yuan.

Tax: Calculated based on specific tax rates, assuming that the tax is 10% of the total cost, the tax is (10+15+5) * 10%=3 yuan.

Overall, the total processing cost is 10 (component cost)+15 (mounting cost)+5 (other expenses)+3 (taxes and fees)=33 yuan.