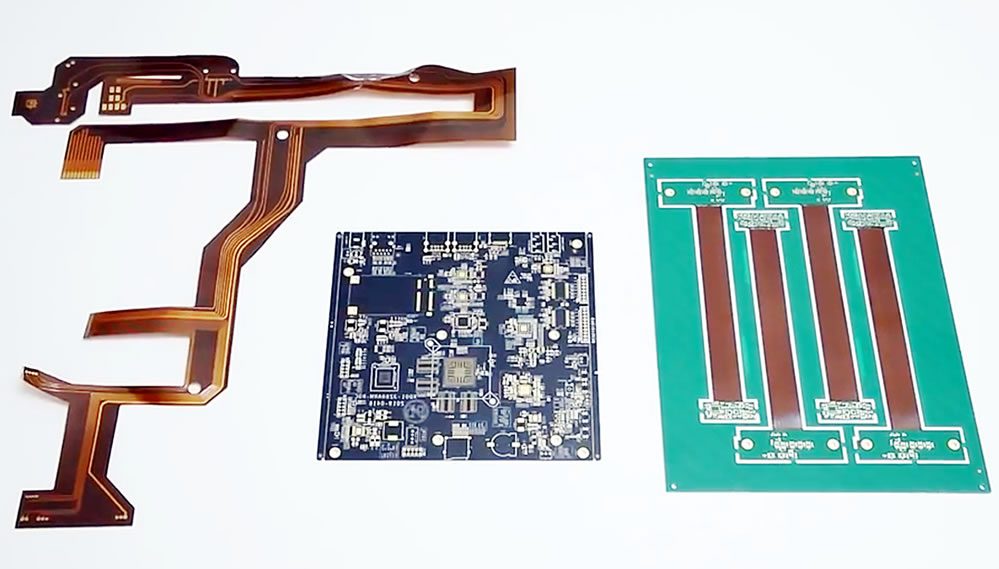

Flexible printed circuit boards (FPCB) are a type of printed circuit board that can be bent and twisted, as well as standard PCBs. They are also known as flex circuits or flex PCBs. These printed circuit boards can be formed into 3D shapes and integrated into other components such as connectors, sensors, antennas, and micro-fluidic devices. Copper foil is the primary conductor in a flex PCB. The copper foil is coated with an adhesive, usually silicone or epoxy resin. When manufacturing a Flex PCB, there are many different production technologies to choose from when it comes to materials used and finishing options available after the board has been produced. When choosing the right manufacturer for your project, there are several things you’ll need to consider before making a final decision on which company will manufacture your boards. This article covers everything you need to know about how to choose the right Flex PCB manufacturer from start to finish.

How to Select a Flex PCB Manufacturer

The best way to select a manufacturer is to first know what you’re looking for. Make a list of all the features that are important to your project and find a manufacturer that can meet those needs. When you know what you want from your manufacturer, it will be easier to narrow down your list of potential companies and find the right one for your project. Not every manufacturer can produce every type of printed circuit board and it’s important to know what they specialize in before selecting them for your project.

Material and Thickness Options

The two most important factors when selecting a Flex PCB manufacturer are the type of copper foil that will be used and the thickness of the copper laminate that will be applied to the board. The copper foil thickness and type of copper have the biggest impact on the overall cost of the board. – Copper thickness: The thickness of the copper foil has a big impact on the price of your PCB. Thicker copper will produce a better-looking and more durable board. However, thicker copper is also more expensive. The standard thickness for a printed circuit board is between 0.05mm and 0.10mm. Thinner boards are easier to work with, but they are also more fragile and have a shorter lifespan. – Copper type: The most common types of copper foil used in printed circuit boards are Annealed Copper, Hard Copper, and Tin-lead. The type of copper used in your board will have the biggest impact on the appearance of the board. Annealed Copper is the most common type of copper used in PCB manufacturing. Hard Copper is commonly used for high-end PCBs that need to look aesthetically pleasing. Tin-lead is typically used for low-cost PCBs.

FPCB Manufacturing Technologies

– Overmolding: Overmolding is a surface mounting technology that uses heat to transfer components from a donor board to a flexible substrate. – Transfer Printing: Transfer printing uses a stamping machine to transfer components from a donor board to a flexible substrate. – Surface Mount Technology (SMT): SMT is a surface mounting technology that uses a solder paste and pick-and-place equipment to transfer components onto a flexible substrate. The type of technology that is used to manufacture your circuit board will have a big impact on the overall cost of the project. However, the technology used to manufacture your boards is less important than the type of components that will be used. – Through-hole components: When choosing components for your flex circuit board, it’s important to select components that are compatible with through-hole technology. – Surface Mount Devices (SMD): Components that are manufactured for surface mounting will cost less than components designed for through-hole.

Are You Manufacturing Through-Hole or SMD Components?

The type of components that will be used on your project will have a big impact on the manufacturing technology that will be used. – Through-hole components: Selecting through-hole components for your board will require a manual process known as wave soldering. – Surface Mount Devices (SMD): Components that are compatible with SMD will be placed manually using a pick-and-place machine.

Reviewing the Manufacturing Process

The manufacturing process is an important factor when selecting a manufacturer, but it’s also something that you can’t change. That said, there are still things you can do to ensure that you’re working with a reputable company. – Ask to see pictures of the factory: It’s a good idea to ask to see pictures of the manufacturer’s factory. This will help you determine if the factory is clean, safe, and properly equipped with the right tools. – Ask to speak with employees: If possible, try to speak with the employees at the factory. This will allow you to get a better idea of how the factory operates. – Ask about quality control: Quality control is an important part of the manufacturing process. Make sure to ask about the manufacturer’s quality control procedures.

Look at Samples of Past Work

If possible, request samples of the manufacturer’s past work. This will give you a better idea of the quality of their products and the overall customer experience. – Ask to see pictures of previous projects: Pictures will give you a better idea of the quality of the manufacturer’s work. This will also help you determine if they have experience working with your components and technologies. – Ask about defects and rework: Defects and rework are normal in any manufacturing process. However, it’s important to know how often a manufacturer has defects and rework.

Pay Attention to Communication and Reputation

The reputation and communication of a manufacturer are just as important as their experience and the quality of their products. – Ask for references: A manufacturer with a good reputation will have plenty of references from happy customers. – Ask about their communication process: You should be able to contact the manufacturer at any time, regardless of what time zone they operate in.

Final Words: Know What You’re Getting Yourself Into

The last thing you want to do is to rush into a decision. A good Flex PCB Manufacturer will have a standard process, so you should expect to go through the same steps with each company. – This process will take time. It’s important to be patient and select a manufacturer that is a good fit for your project. – Remember, not every manufacturer can produce every type of printed circuit board. When you know what you want, it will be easier to find the right company for your project.