As the foundation of PCB products, boards are not only the core and main raw materials, but also account for about 60% of PCB costs. The importance of sheet metal is self-evident. The saying goes, only good ingredients can make good food. Good boards ensure good quality. Therefore, when making PCBs, selecting the right board is the key.

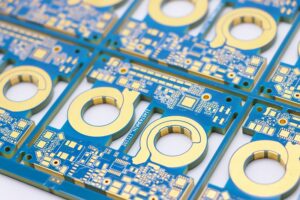

Especially for multi-layer PCBs. Due to its high integration, small size, excellent signal integrity, and excellent thermal management capabilities, it is widely used in various fields such as consumer electronics, communication equipment, automotive electronics, industrial control and automation, medical equipment, aerospace, and energy equipment.

Taking the field of automotive electronics as an example. With the rapid development of automotive electronics technology, the application of multi-layer PCBs in the automotive industry is becoming increasingly widespread. Its high-density layout and reliable performance meet the needs of automotive electronics for miniaturization, high reliability, and environmental adaptability. So, multi-layer PCBs are applied in car entertainment systems, driving assistance systems, engine control units, and safety systems.

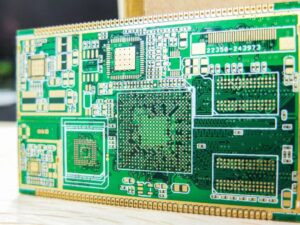

Compared to single-layer or double-layer PCBs, high multilayer PCBs face higher complexity and performance challenges. This is mainly reflected in three aspects: first, the requirements for high-frequency signal transmission characteristics. High multilayer PCBs are commonly used in applications that require high-frequency signal transmission, such as communication devices and high-speed digital signal processing. This requires PCBs to have better dielectric performance and signal transmission speed to reduce signal loss and noise.

The second is the demand for thermal management. High multilayer PCBs are commonly used in high-power electronic devices and require effective thermal management measures to ensure the normal operating temperature of components. This requires PCBs to have better thermal conductivity and thermal expansion coefficient control to optimize heat conduction and distribution, avoid hot spots and thermal stress issues.

The third requirement is mechanical strength and stability. High multilayer PCBs typically have larger dimensions and higher layers, therefore requiring higher mechanical strength and stability. The rigidity and durability of the board are crucial for resisting vibration, impact, and bending stress to ensure the reliability and lifespan of high multi-layer PCBs.

It can be seen that high multilayer PCBs have higher requirements for the board, including special requirements in high-frequency signal transmission, thermal management, and mechanical strength stability.