NEWS

How is the cost of SMT calculated?

The cost of SMT surface mount processing involves components, surface mount technology, soldering materials, quality control, and other costs. The calculation formula is based on factors such as component quantity, unit price, number of mounting points, and unit price.

What documents are required for SMT sample production?

SMT sample manufacturing is a complex and precise process that requires customers to provide comprehensive and accurate design and production data.

In PCBA SMT processing, the component baking process is also important

In PCBA SMT processing, component baking is crucial. Before baking, it is necessary to screen, classify, clean, and inspect equipment.

PCBA machining accuracy requirements

The precision of PCB processing involves aspects such as chip placement, welding quality, and electrical performance testing, which require strict monitoring and adjustment to meet the requirements.

SMT point calculation quotation

In SMT chip placement processing, calculating the number of points and quoting is crucial, involving factors such as the quantity, type, board, and order quantity of components.

The key links of one-stop PCBA services

The biggest advantage of one-stop PCBA services lies in their convenience and efficiency.

SMT production environment requirements

SMT surface mount processing requires strict control of the production environment, including suitable temperature and humidity, dust prevention, electrostatic protection, and good lighting and noise control.

What tests are performed after PCB soldering?

The key to PCB welding quality inspection includes visual inspection, electrical testing, X-ray testing, automatic optical testing, and environmental adaptability testing.

Standard requirements for PCBs of medical equipment

Medical PCBs have high standards and must meet requirements such as electrical safety, environmental adaptability, EMC, high precision, and medical regulations to ensure product quality and safety.

How to manually handle tin connection in PCB process

In the PCB process, if there is tin connection, especially during manual soldering, the following steps can be taken to ensure that the quality and performance of the circuit board are not affected. The following is a clear processing flow

The characteristics of SMT electronic assembly

SMT electronic assembly plays a crucial role in the electronic manufacturing industry due to its efficient, precise, and reliable production steps and

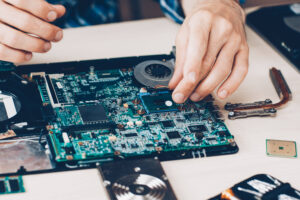

What processes do SMT surface mount processing require?

SMT surface mount processing involves preparation, printing, surface mount, welding, and inspection and repair processes to ensure accurate installation of electronic components on PCBs.