NEWS

How to avoid virtual soldering during SMT processing?

Virtual soldering in SMT processing affects product quality, and it is necessary to optimize welding materials and processes, strengthen PCB board and component management, finely control each process, and strictly inspect and repair quality. Avoid virtual soldering and enhance product competitiveness.

What industries are suitable for small batch SMT surface mount processing?

small batch SMT surface mount processing services are gradually becoming a favored choice for many industries. This service model is not only flexible and efficient, but also effectively reduces production costs and risks, making it particularly suitable for industries with customized and diversified needs for electronic products.

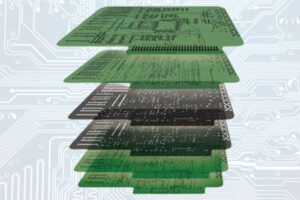

How do the number of PCB layers affect the efficiency and quality of SMT processing?

The number of layers on a PCB (printed circuit board) has a significant impact on the efficiency and quality of SMT (surface mount technology) processing. Including the following factors: wiring density and processing difficulty, thermal conductivity and soldering quality, interlayer insulation and processing stability, design flexibility and manufacturing cost.

The difference between the inner and outer layers of PCB

There are differences in position, function, manufacturing, and cost between the inner and outer layers of PCB. The inner layer is responsible for electrical connections, which is complex and costly to manufacture; The outer layer is connected to the outside world, with simple manufacturing and low cost, but it needs to consider aesthetics and wear resistance.

Why is it necessary to bake the PCB board before SMT mounting?

baking PCBs is to ensure that components can be reliably soldered to the PCB surface during SMT surface mount processing, improving product quality and reliability.

The details of SMT processing cannot be ignored

In the field of SMT processing, details determine success or failure. From material selection to environmental control, from equipment calibration to process optimization, to strict quality inspection, every step needs to be carefully planned and executed.

How to apply three proof paint on PCB?

PCB coating with three proof paint can protect PCBs from harsh environmental erosion and extend the lifespan of electronic products,Its main function is to form a transparent protective film on the surface of the PCB, preventing external factors such as moisture, salt spray.

The key role of steel mesh in SMT process

In SMT technology, the stencil is a seemingly simple yet extremely critical component. It is a thin metal plate with holes precisely etched on it according to the PCB design, corresponding to the component pads.

Application of lead free technology in PCBA processing

Lead free technology refers to the use of lead-free solder for soldering during PCBA processing, replacing traditional lead containing solder. This change is mainly driven by environmental regulations

Burning process in PCBA processing

burning refers to writing pre written program code into the memory on the PCBA board. This process enables the device to work according to the requirements of the program and achieve the expected functions.

Detailed explanation of PCB surface mount processing technology from SMT to BGA

The PCB surface mount processing technology covers raw material preparation, PCB board making, SMT surface mount, DIP packaging, BGA packaging, and subsequent processing and testing. Each link is related to product performance and quality.

Why do we need to clean PCBA after processing

Cleaning is crucial in PCBA OEM material processing, as it can remove surface dirt and residues, enhance insulation performance, improve corrosion resistance and appearance quality。