NEWS

How to optimize the process parameters of SMT surface mount processing?

In SMT surface mount processing, optimizing process parameters is very important, such as welding temperature and time, surface mount pressure and speed, substrate processing and cleaning process parameters need to be finely adjusted

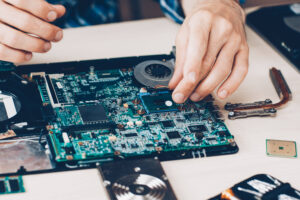

In depth analysis of equipment required for PCBA processing and assembly

In the field of electronic manufacturing, PCBA is a critical process, and achieving high-quality PCBA processing and assembly requires the support of a series of professional equipment.

Welding Quality Standards in PCBA Processing

Welding is a crucial step in PCBA processing, and its quality standards mainly include the following aspects:Welding fullness、Solder Paste Quantity Control、Component misalignment、Floating phenomenon、Tin bead management。

What are the components of PCBA OEM material prices

The price of PCBA outsourcing includes PCB manufacturing costs, material procurement, SMT/DIP plugins, testing, assembly, packaging logistics, and profit margins.

How important is a standardized BOM in PCBA

The BOM table refers to the bill of materials. Before PCBA processing, customers are required to provide the latest BOM table, which includes all electronic components and other materials required for the production of this product

What is the difference between PCBA processing and SMT processing?

The difference between PCBA processing and SMT processing: 1 Different production processes, 2 Different types of components, 3 The production cost varies.

Cost control factors for SMT surface mount

SMT is an important link in the field of electronic manufacturing, and its cost control has a crucial impact on the profitability and market competitiveness of enterprises.

Comparison between SMT Processing and Traditional Plug in Technology

With the continuous development of electronic manufacturing technology, surface mount technology (SMT) processing and traditional plug-in technology have become the two mainstream processes in the field of electronic assembly.

How is the cost of SMT calculated?

The cost of SMT surface mount processing involves components, surface mount technology, soldering materials, quality control, and other costs. The calculation formula is based on factors such as component quantity, unit price, number of mounting points, and unit price.

What documents are required for SMT sample production?

SMT sample manufacturing is a complex and precise process that requires customers to provide comprehensive and accurate design and production data.

In PCBA SMT processing, the component baking process is also important

In PCBA SMT processing, component baking is crucial. Before baking, it is necessary to screen, classify, clean, and inspect equipment.

PCBA machining accuracy requirements

The precision of PCB processing involves aspects such as chip placement, welding quality, and electrical performance testing, which require strict monitoring and adjustment to meet the requirements.