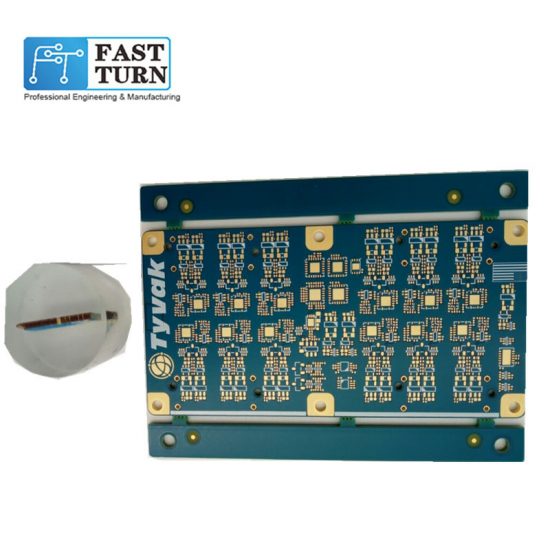

In the PCB market, the Fast Turn PCB is now creating a buzz as a leading high-tech company in Prototype PCB Board. Its Research and Development (R&D) team had an intensified twenty-one years of experience in developing a high-end prototype PCB Board.

Having a prototype board of PCB entails a lesser cost in having an “idea” be finalized or before finalizing the printed circuit board. It is just like a “blueprint” for the final PCB. There are various types of PCB prototypes of which you can finally plan or decide for the final output of the design of the PCB.

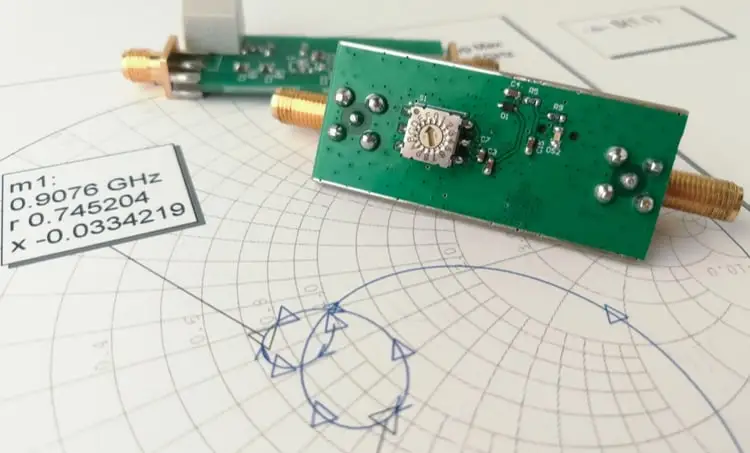

The electronics designer like Fast Turn PCB has the necessary technical skill to build a prototype from the stripboard, breadboard, or perfboard and eventually uses it to test circuits. Prototyping is the common parlance being used to refer to this Prototype PCB Board, and it has holes in which the electronic components are affixed in order to build the final circuit.

Fast Turn PCB had been in this technical field since 2007, which earned its mark in the PCB industry with a PCB production shop and as well as a PCB assembly shop. Its expertise is building a multilayer 4-50 multilayer, hard gold board, rigid-flex, HDI blind, and buried board.

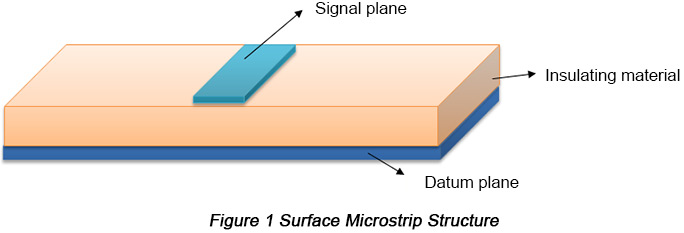

In the simplest concept, a Prototype PCB Board supports mechanically and electronically the different electronic components that use conductive tracks and pads attached to the numerous sheets of layers of copper laminated into the non-conductive substrate sheet layers. PCB is also being used in other electrical products like a passive switch box.

There are some alternatives for PCB in the market, such as point-to-point construction or a wire wrap, but it is now rarely being used. A PCB design is needed to finally lay out the circuit, which can be built by an electronics manufacturer like “Jujin.” Making that layout requires an electronic computer-aided design software readily available at Jujin or commonly called Fast Turn PCB. It has the capability to fabricate a large number of PCBs.

In comparison with other wiring methods, PCB is considered the cheapest and fastest in mass-producing circuits. In small quantities, PCB can be manually made in small quantities, but many PCB needs need to be fabricated, and a layout must immediately be made.

There are various types of Prototype PCB Board in the market, such as single-sided (one copper layer) a double-sided, wherein both sides of the substrate have two copper layers. The last one is multi-layer which has alternating layers of inner and outer layers of copper in a substrate.

Among the different types of Prototype PCB Board, the multi-layer is now becoming a fad for its capability for a higher component density. Usually, a multi-layer PCB has a two or more copper planes that can be concurrent to the adoption of the surface mount technology. However, it also has a noted drawback in using a multilayer PBC for its difficulty in making repairs, analysis, and circuit field modifications.

Fast Turn PCB can guide you on which type of Prototype PCB Board is suited to your needs. It has the technical expertise to build the different types of Prototype PCB Board, and it ensures that it can deliver a quality product in a short span of time. It puts value to the quality of their work and as well as to time. It has a bragging right to making an expedited delivery for single-sided, double-sided, or even to a multi-layer PCB.