PCB Quality System

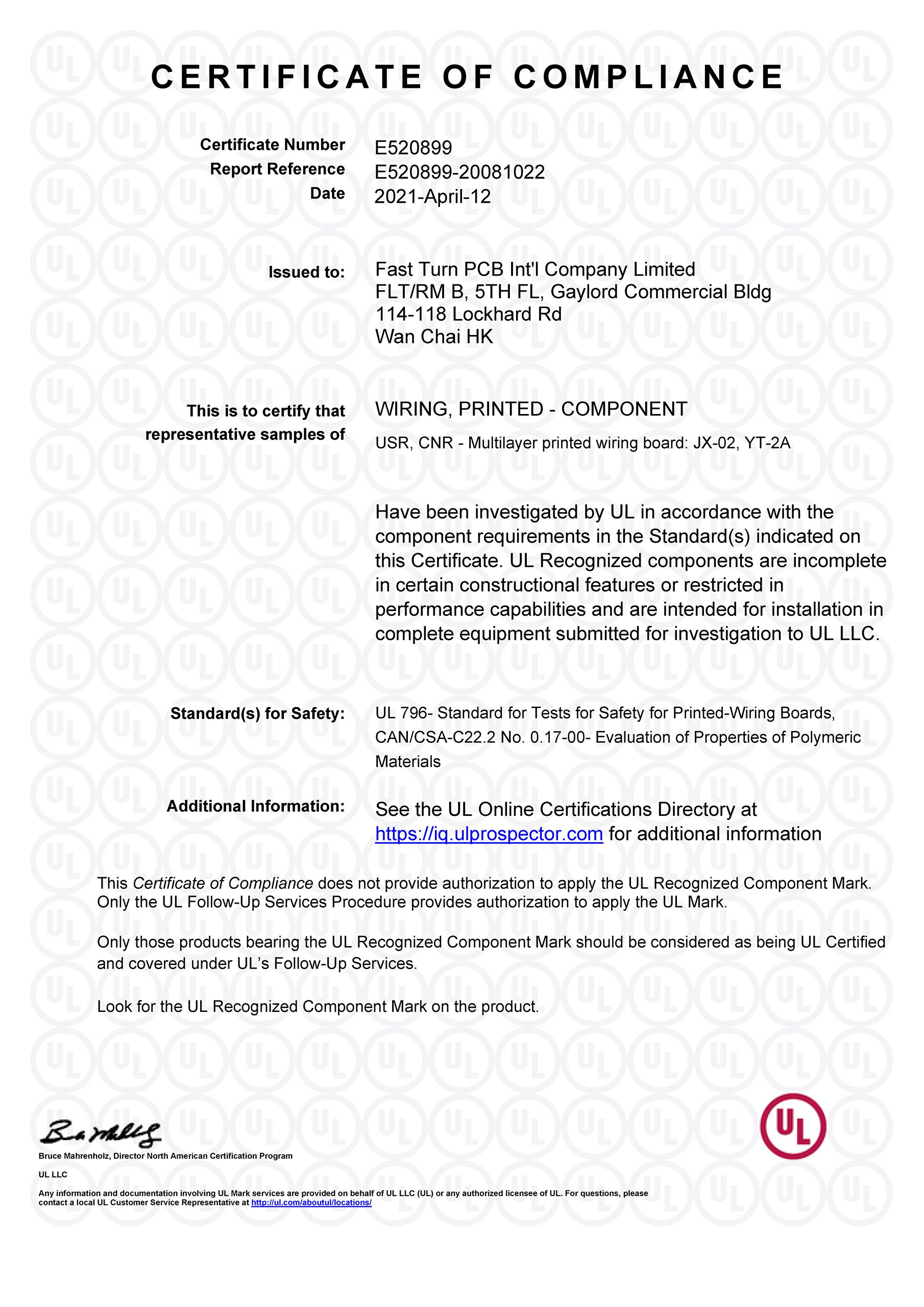

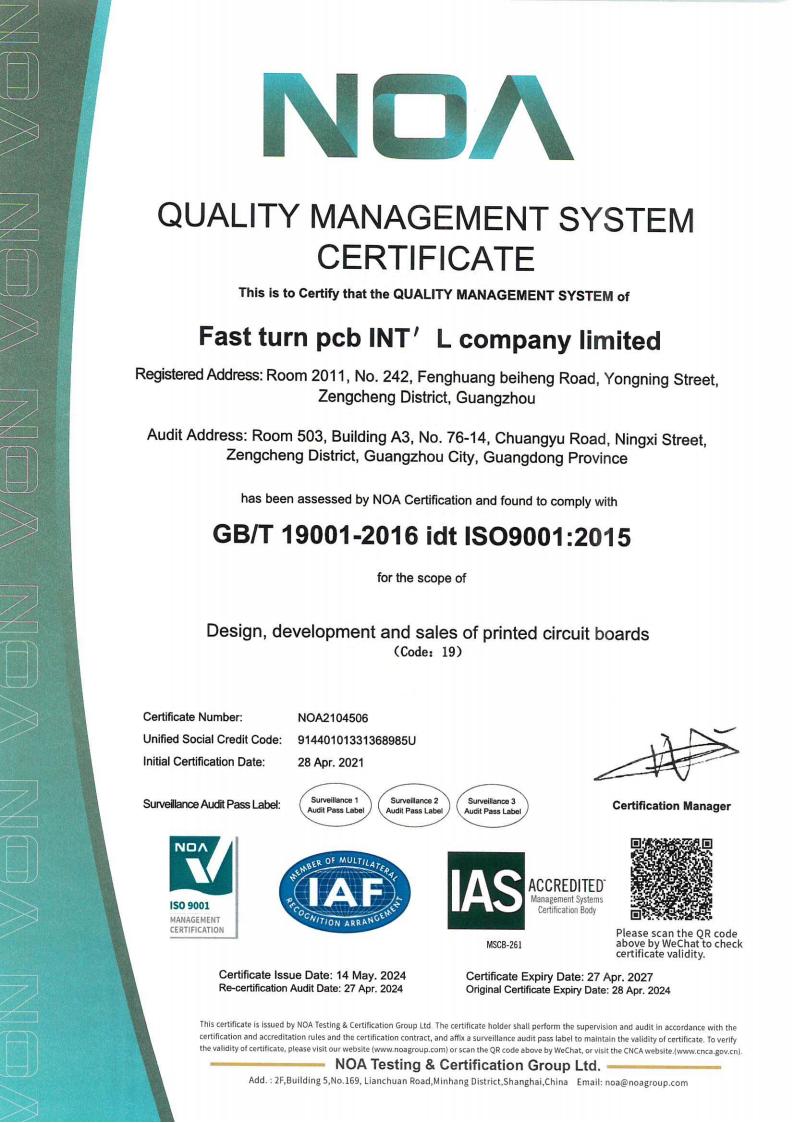

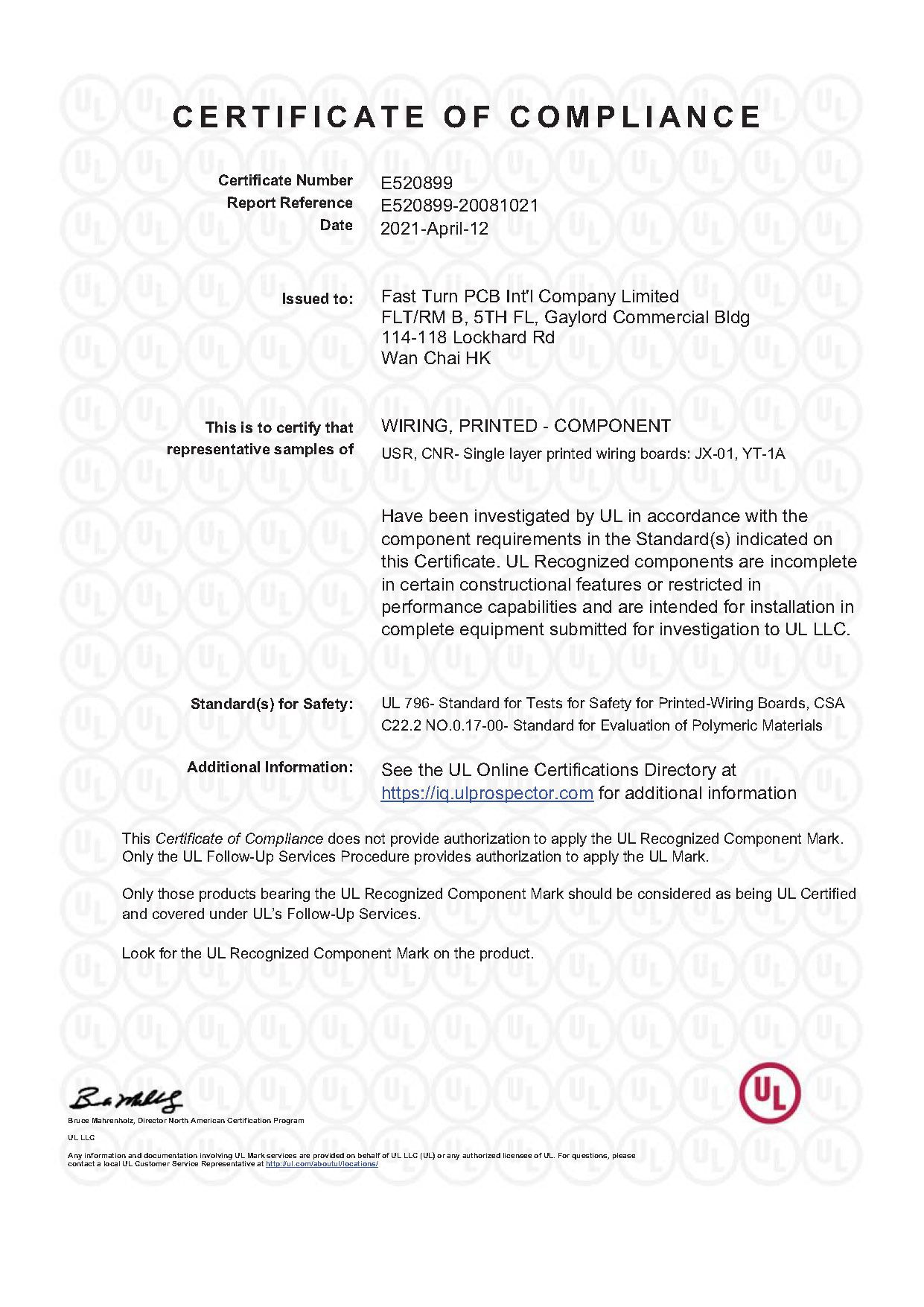

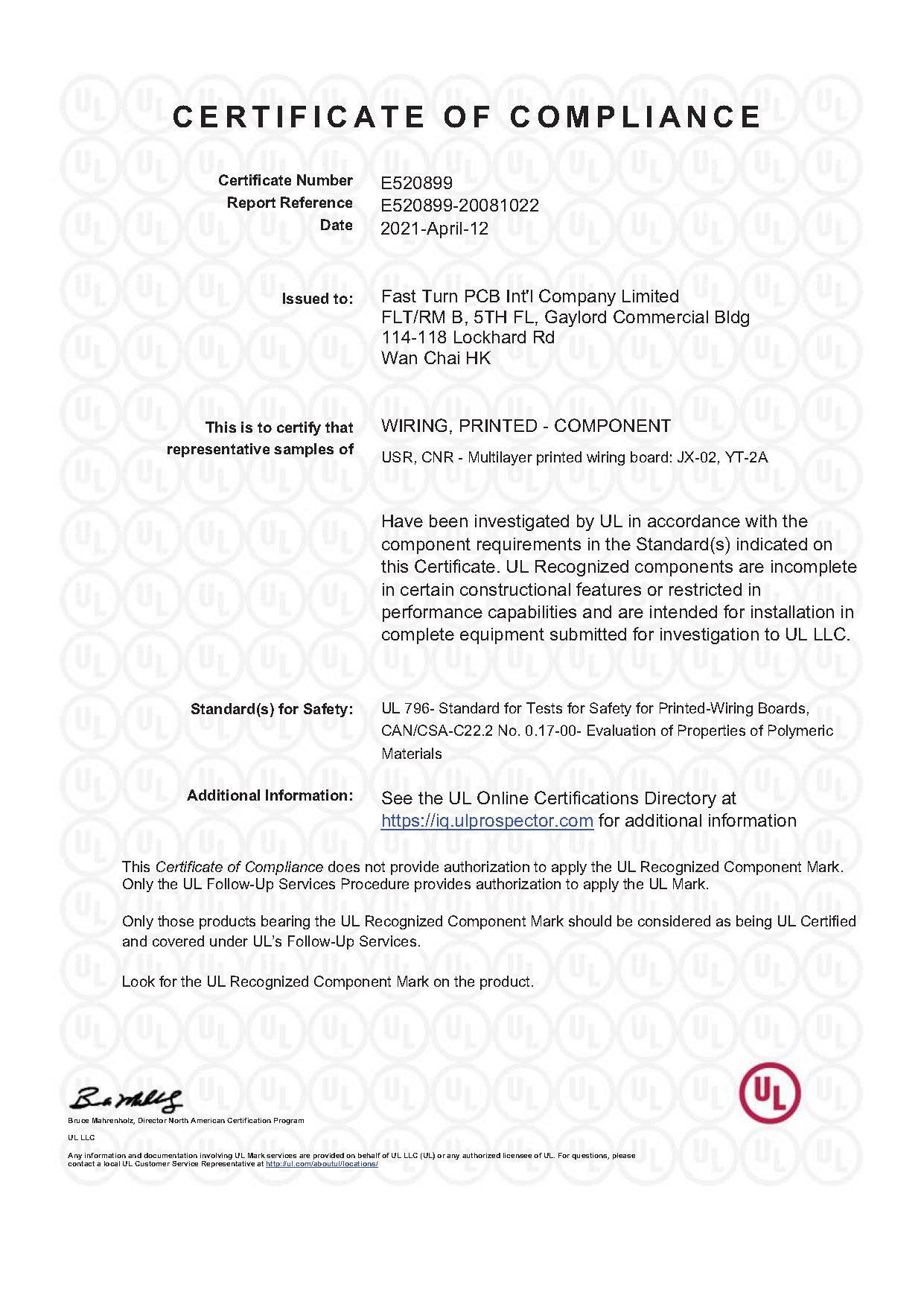

The quality management system and product quality have passed ISO9000, 14000 environmental certification, enterprise credit rating certification, ROHS certification, REACH certification, etc.

The key quality process control is as follows.

(1) We conduct strict incoming inspection of materials

(2) Our warehouse will control the material on a first-in, first-out basis

(3) After the engineering CAM does the DFM, there will be engineering QA to check the documents

(3) The factory uses ERP system to control the whole process, the online board will go with the process card and the customer’s drawing instructions

(4) The inner layer will be made by LDI, and 100% AOI inspection will be done.

(5) After lamination, the board thickness will be measured and checked by X-ray for misalignment, and the thickness of the inner media will be checked by slicing to avoid stacking the wrong board.

(6) After drilling, we will use the drilling point chart to check if there are any missed, over-drilled, over-drilled or under-drilled holes.

(7) PTH copper sinker will be sliced to check if the hole copper meets customer requirements

(8) Vacuum etching line will be used for the outer circuit, and 100% AOI inspection will be done, for high density boards to do semi-finished products open short circuit test

(9) After doing solder resist, we will do full inspection to prevent solder resist bias, more or less printing

(10) After milling the board will be 100% electrical test, for impedance board will do impedance test and provide relevant test reports

(11) Each board will be 100% machine or manual FQC before delivery, to ensure that the customer receives the correct board

(12) For small quantity and batch orders, the first board will be confirmed in each process.

_00.jpg)

_00.jpg)

PCB Quality Assurance

To continuously improve quality and service through continuous improvement.

To create and maintain the “FASTTURN” brand to meet customer expectations.