rapid pcb prototyping

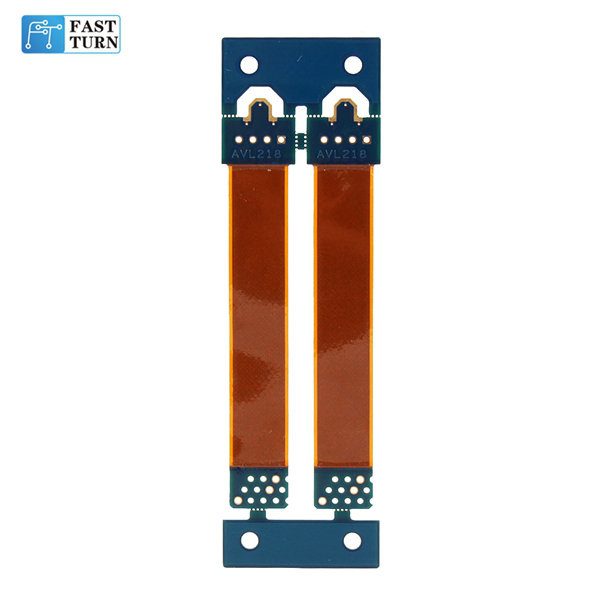

Rapid Pcb Prototyping Of Impedance Control Rigid Flex Pcb Circuits Boards

| Layer: | 4 | Material: | FR4 S1000-2+Panosonic Polyimide |

| Thickness: | 1.6 mm for the whole board with 0.2 mm flex part | ||

| Min.Line width: | 4mil | Min.Hole size: | 10mil |

| Surface control: | Immersion gold | Copper thickness: | 1 OZ |

| Impedance control: | Yes | Leading time: | 5 working days |

Technological advancements require constant invention, and new ideas demand new iterations. Developers know that each new idea needs to be designed, built and tested to determine how to further improve the design for their needs. Most developers utilize prototyping for this purpose.

While prototyping is an essential need for the design process, PCB designers face a unique challenge in this area — prototyping is a significant bottleneck in the design process. Many manufacturers don’t take small orders, and if they do the prototype takes a long time to complete. Not only does this long lead time curtail the creative process, but it also slows down time to market.

One solution to this challenge is rapid printed circuit prototyping.

WHAT ARE THE BENEFITS OF A RAPID PCB PROTOTYPE?

Rapid PCB prototype fabrication services are valuable for the creation of electronic devices. Companies using rapid PCB prototyping can enjoy the following benefits:

Quick turnaround: The most significant benefit of rapid PCB prototyping is speed. Rapid PCB prototyping services provide quick turnarounds, reducing the fabrication time from weeks to hours. This speed of fabrication supports the creative design process by minimizing wait times, which, in turn, reduces the design and testing phase of PCB development.

Accurate results: Prototypes allow designers to observe and test every circuit design and function accurately. Prototyping delivers a functional replica of the PCB design to the tester so that they can get an accurate representation of how the final product will work. Accurate boards help designers determine how to change the PCB layout for optimal functionality.

Modification flexibility: Faster prototype fabrication allows designers to be much more flexible with regards to modifications. By receiving prototypes more quickly, designers can spend more time verifying and assessing the functionality of each iteration and making adjustments.

Small volumes: Rapid prototype services produce small quantities of prototype boards for testing, so your company doesn’t need to waste money on dozens of prototype boards you don’t need.

Customer satisfaction: The goal of every designer is to achieve high-quality PCB products to satisfy their customers. Rapid PCB prototyping helps achieve this by allowing for more thorough testing and design modification while minimizing turnaround times. Additionally, customers can see the design process in real time with physical boards to observe.

Cost reduction: PCB prototypes enable companies to reduce their costs by allowing designers to test boards and find problems before the production run. Rapid prototyping further reduces costs by accelerating the testing and verification processes, which reduces manufacturing and design costs for each project.

These benefits of PCB rapid prototyping are valuable for the industry, allowing designers to achieve greater innovation in shorter timeframes compared to their competitors.

RAPID PCB APPLICATIONS

Rapid PCB prototyping is valuable for nearly any electronic design application. However, some industries benefit greatly from rapid prototyping in their development cycles — some of those industries and their rapid prototyping needs are described below:

Medical industry PCBs: Technology developers in the medical industry often use rapid PCB prototyping in the development cycle. PCBs within this field are used in implants, imaging devices and lab equipment used to diagnose and treat diseases, so optimal functionality is critical. Prototyping allows designers to test the functionality of each PCB before it goes into production, ensuring the PCB functions as needed. Rapid prototyping further improves results within this industry by allowing for faster and more thorough testing.

Automobile industry PCBs: Nearly all modern cars are equipped with electronic smart systems, which are run by PCBs. From safety features to temperature control, PCBs control it all, so it is critical that they work correctly. Prototypes ensure each PCB used in an automotive design reliably meets all functional requirements before a full production run is underway.

WHAT TO LOOK FOR IN A RAPID PCB PARTNER

If your company is looking for rapid PCB prototyping services, there are several key features to look for. Some of these features and services include the following:

Instant quotes: Look for vendors that offer quick quotes for the services you request. If the quote process is slow, you can’t expect their services to be any faster.

Quick turn manufacturing: Choose to partner with suppliers that have the machines and processes to support your quick turn needs.

Experience: Look for PCB services backed by years of experience. Experienced PCB service companies know what is needed for a successful project and carry the certifications to back up their knowledge and capabilities.

If you find a PCB prototyping service that offers these features and services, you can trust that your rapid PCB prototyping is in the right hands. For a prototyping service that offers these features and more, Fast turn Circuits Limited (MCL) has your project covered.