As an important component in the electronics industry, the golden finger plays a crucial role in circuit board connections and data transmission. Next, let’s delve deeper into what circuit board gold fingers are.

1、 The definition of the golden finger

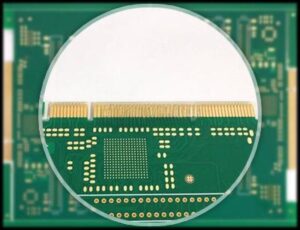

Gold Finger, also known as Edge Connector in English, is a row of golden conductive contacts on a circuit board (PCB). These touchpads are usually coated with gold and are named “Golden Fingers” because they resemble fingers in shape.

2、 The function of the golden finger

Gold fingers play a crucial role in circuit boards. It is not only a bridge connecting circuit boards to the outside world, but also bears the heavy responsibility of data transmission. Due to its superior conductivity, wear resistance, oxidation resistance, and corrosion resistance, Gold Finger can ensure stable connection and data transmission of circuit boards in various environments.

3、 Classification of Golden Fingers

Gold fingers can be classified into different types based on their shape and arrangement, mainly including:

Regular gold fingers (flat fingers): These types of gold fingers are neatly arranged at the edge of the board, with the same length and width. Commonly seen in devices such as network cards and graphics cards.

Long and short gold fingers (i.e. uneven gold fingers): These types of gold fingers have varying lengths and are commonly used in devices such as memory, USB drives, and card readers.

Segmented Gold Fingers (Intermittent Gold Fingers): These types of gold fingers have varying lengths at the edge of the board and have a broken part at the front end.

4、 The production process of golden fingers

The manufacturing process of gold fingers is very delicate, requiring electroplating of hard gold to increase wear resistance, and usually requiring chamfering at 45 ° or other angles. At the same time, in order to ensure the conductivity of the gold finger, it is necessary to perform a whole block solder mask window treatment. In addition, the surface of the golden finger should not be covered with copper, while the inner layer needs to be treated with copper cutting.

As a key component in electronic devices, the quality and performance of circuit board gold fingers directly affect the stability and data transmission efficiency of the equipment