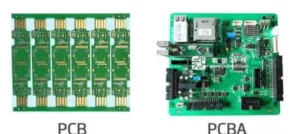

PCBA and PCB are commonly used terms in the manufacturing process of circuit boards, and their differences are as follows:

1. Conceptual differences:

PCB usually refers to printed circuit board, which is a board with electronic component pins and electrical circuits; PCBA, on the other hand, is a printed circuit board assembly board based on the design requirements of PCB, which is completed through the layout, welding and other process flows of various electronic components.

2. Differences in manufacturing processes:

PCB manufacturing usually includes processes such as finished product production, CNC processing, forming, copper coating, drilling, and outer product production; PCBA manufacturing includes multiple processes, including component procurement, SMT, hole insertion, and post welding process.

3. Application differences:

PCB is usually the carrier of the core components of various complex electronic products, such as mobile phones, televisions, home theaters, etc; And PCBA is a finished electronic product, such as computer motherboards, industry control circuit boards, etc.

4. Differences in characteristics:

A PCB is a flat circuit board filled with air or other insulating materials, which can realize the circuit connection of electronic components and the transmission of mutual signals, and has a lower cost of use; On the basis of PCB, PCBA has added the soldering process of components, which can achieve circuit board assembly and practical applications.

In summary, although PCB and PCBA have very similar names, they have obvious differences. As the core component carrier in electronic products, PCB plays an important role in electronic design and production processes; PCBA, on the other hand, is an intermediate stage product that involves adding components to a PCB and assembling finished electronic products.