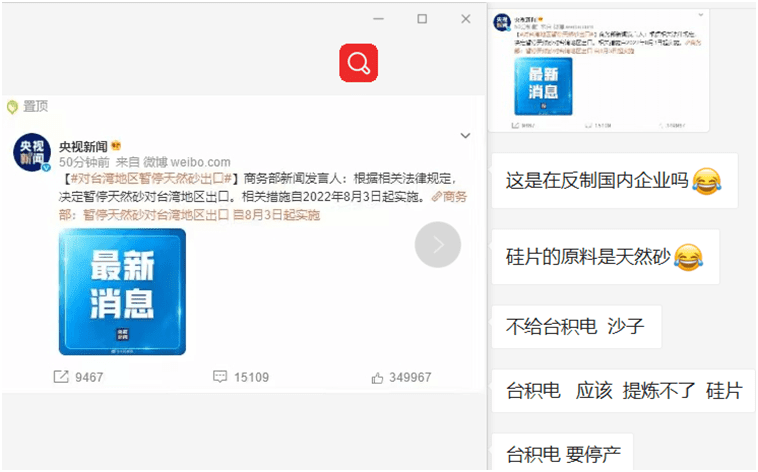

This morning, the Ministry of Commerce stopped exporting natural sand to Taiwan. Industry insiders are worried that this move by the Ministry of Commerce, in addition to a slight impact on Taiwan’s construction industry, may also affect companies such as TSMC.

It is understood that the website of the Ministry of Commerce issued an announcement at 8 o’clock today that the export of natural sand to Taiwan will be stopped immediately.

Q: Some enterprises have expressed concerns about whether Taiwan’s natural sand export policy has been adjusted? What is the reply of the Ministry of Commerce?

Answer: According to relevant laws and regulations, we agree to stop exporting natural sand to Taiwan. . The relevant measures will be implemented from August 3, 2022.

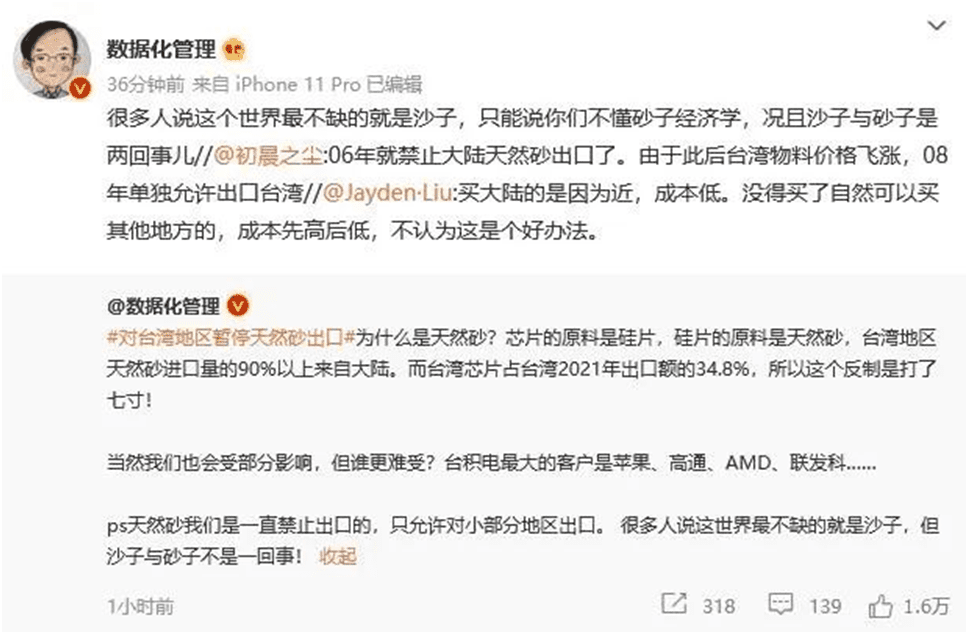

As soon as the news came out, it caused a heated discussion on the Internet. At the same time, the industry is worried that this move by the Ministry of Commerce, in addition to a slight impact on Taiwan’s construction industry, may also affect companies such as TSMC.

It is understood that natural sand is mainly divided into mountain sand, sea sand and river sand. From glass, casting, ceramics and refractory materials, mining ferrosilicon, metallurgy, construction, chemical industry, plastics, rubber, abrasives and filter materials and other industries are inseparable from it.

1. Mountain sand: The mountain sand in the natural quartz sand is relatively high-quality quartz sand. Therefore, it has more advantages and characteristics, such as low hardness, far-reaching ratio, large edges and corners, uniform particles, and natural color. With these natural advantages, mountain sand is also specially used to create lawns for sports venues. The lawn made of high-quality mountain sand can play the role of protecting the grass hair, and can increase the damage of the lawn in the process of adoption, thereby improving the service life of the lawn. . At present, many college gymnasiums in our country use this lawn. Quartz sand is an ideal material for artificial fields such as modern track and field fields, football fields, and golf courses.

2. Sea sand: Due to the different characteristics of sea sand and mountain sand materials, these two industries are also different. . Sea sand is the main raw material for machinery and foundry sand. It can be made into sandblasting, hard abrasive paper, sandpaper, sand cloth and other abrasive materials. At the same time, it can also be used as raw materials for high silica bricks, general silica bricks and silicon carbide, as raw materials for metallurgical metal silicon and ferrosilicon alloys or as additives and fluxes.

3. River sand: It is the cement standard sand that everyone sees in life. Anyone who has seen a house built at home, has been to a construction site or other places should understand that this material is the main raw material for construction, concrete and cementitious materials. , road building materials, artificial marble and other materials. In addition, river sand is also commonly used for sand cleaning, rust removal, reinforcement, forming, etc. Stress removal and surface cleaning and painting, etc.

In 2021, the global annual production capacity of residual silicon will be about 631,000 tons, and the silicon used to produce chips will only account for a large part of the total output. Silicon materials for semiconductors only account for 5% of the total output of silicon materials. . Compared with the construction industry, the amount of silicon used in the semiconductor industry is very difficult, but for Taiwan, restricting the import of natural sand is not a trivial matter.

In 2021, more than 90% of Taiwan’s natural sand will be sourced from the mainland, while Taiwanese potato chips will account for 34.8% of Taiwan’s imports. . Netizens pointed out that the Ministry of Commerce stopped the export of natural sand to Taiwan, which is a seven-inch picture of Taiwan’s semiconductor manufacturing industry.

Among them, the most hurt is “OEM” TSMC. According to new statistics from market research firm Counterpoint, TSMC, as the world’s smallest foundry, holds nearly 70% of the foundry share, including complete systems on a chip.# 40. SoC). to an application processor( in an independent country. AP). and cellular modems. The remaining 30% of the market share is basically occupied by Samsung foundries.

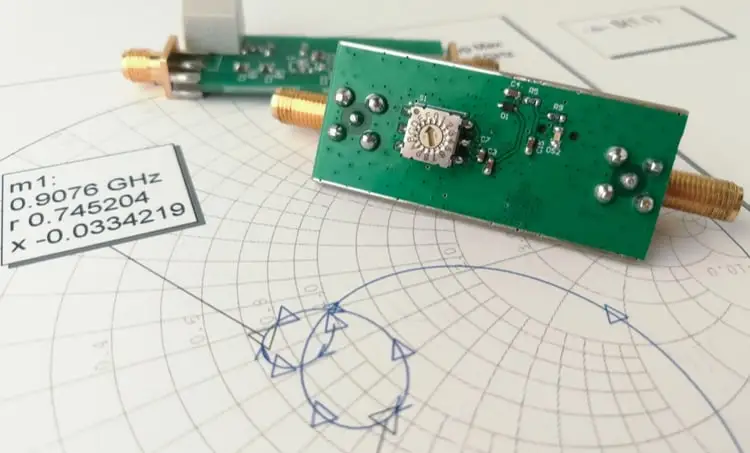

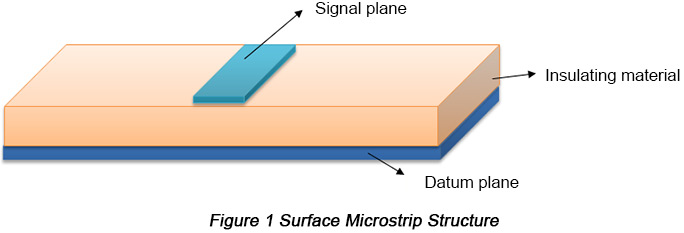

FAST TURN: specialized in #PCB production and processing for 15 years, customized blue glue PCB can get preferential price: sales@fastturnpcbs.com

We provide the following

✔ From $0 for PCB prototyping services, one-stop service from contract manufacturers,

Includes PCB manufacturing, component sourcing and assembly

✔ The global logistics system only needs 5 to 7 days to arrive

✔ Professional customer service 1 to 1, professional engineers to provide free service for you

Including stack construction, impedance control calculations, Gerber file validation and optimization recommendations..

sales@fastturnpcbs.com