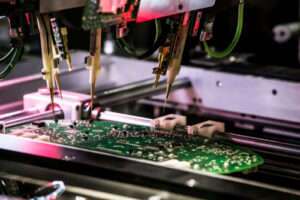

Electronics manufacturers need a dependable partner to supply the electronic chip that goes into all our smart electronic gadgets. Whether it’s a luxury car or smartwatch, a remote-controlled child’s toy or a glucose monitoring kit at your local health store, the crucial printed circuit board (PCB) is an essential component.

Manufacturing a PCB involves a series of complex steps: printing and storing circuit boards, procuring electronic components, assembly, and testing to ensure functionality to specifications. Traditionally, OEMs used a multi-vendor, multi-partner approach to PCB sourcing, manufacturing, assembly, and testing. However, this method was too cumbersome, slow, expensive and error-prone. As a result, the demand for ready-to-use PCBs snowballed, and one-stop PCB assembly services became the preferred choice for electronics manufacturers and designers.

The importance of a one-stop PCB assembly services provider

End-to-end service providers give OEMs a competitive edge. They can turn their ideas into efficient electronics products, get them out into the market before their competition, and achieve early monetization.

When working with a one-stop PCBA (printed circuit board assembly) service provider, the same vendor sources components and assembles the PCB. Maintaining a single point of contact for the entire manufacturing process eases communication in case of any problems, changes, or modifications. As a result, you can resolve issues quickly and efficiently, eliminate bottlenecks in the production process, and significantly reduce PCB production lead times.

Fast Turn PCB is your ideal partner for one-stop PCB assembly services. We procure high-quality electronic components based on your PCB design. Our advanced electronics assembly solutions and superior customer service support you throughout the assembly process till the PCB board is tested and shipped to your promises.

OEMs prefer to work with one-stop PCB assembly manufacturers to provide services at every production stage:

Components procurement: Careful selection and timely procurement of components are key to an efficient PCB assembly process. The MIS procurement team studies details of the PCB design and layout before placing the orders for components to avoid problems in the layout later on.

Component placement: If the electronic components are not placed correctly on a blank circuit board, it can cause problems during assembly. It may result in incorrect soldering and can even cause shorts and failures in some or all of the automated processes.

PCB board layout: The schematic layout of the circuit board is decided during the PCB design process. Design choices affect the cost and delivery schedule of PCBs. Complex PCBs require longer procurement lead times and fabrication time. Therefore, coordination with the design team is critical to meeting cost and delivery targets. A one-stop provider can keep track of all the connections or interfaces that the design may require and accommodate them in the manufacturing schedule and costs.

Testing: Fast Turn PCB provides comprehensive testing services for PCB components and functionality. Our powerful tests include Automated Optical Inspection (AOI), X-Ray tests, in-circuit tests, flying probe, Jtag. We will not let any board pass through unless it’s perfect!

Fast Turn PCB partners with you from the PCB design phase to maximize the benefits of DFM for product development, including making the right components selection and placement decisions, and finally through to production and testing.

The advantages of using one-stop PCB assembly services

Reduce PCB fabrication and assembly costs: Since our one-stop PCB services cover all processes, including fabrication and assembly, there is no need for shipping components and boards from one vendor to another. Your Bill of Materials (BOM) cost is also optimized as we efficiently source difficult-to-find and long lead-time components. With all processes under one roof, you save on production costs.

Detect errors and issues early: An end-to-end service can spot potential errors and detect potential issues very early in the PCB assembly project. This saves time and gives you a chance to modify the design and reduce wastage, resulting in substantial cost savings.

Ensure higher quality of parts and production: It is best to get a single outsourced company to manage the entire production process for quality assurance. With multiple vendors, errors at one stage may not get communicated to the next, leading to quality issues in the end product. We constantly review our quality management system to enhance service delivery. We select only high-quality components from proven suppliers.

Maintain easy communication with a single point of contact: When you have a single point of contact, there is better collaboration between designers, engineers, and testing teams. You don’t need to circulate design files with multiple vendors—one error in a chain of vendors can cause delays and quality issues in the final assembly phase. A single point of contact makes it easy to initiate change order changes with a simple phone call or email.

Develop, test and take products to market faster: To compete in today’s fast-paced market, you need to turn your ideas into thoroughly tested and functional products in the quickest time possible. Work with a single partner for shorter procurement lead times, smoother production, and a faster time-to-market while delivering quality products to your customers. We handle all aspects of the PCB manufacturing process so you can focus on improving the performance of your final product and designing better products!