TURNKEY PCB ASSEMBLY

PROTOTYPE TO MASS PRODUCTION

10 Years in PCB Assembly

PCB Assembly Service

FAST TURN is an ISO9001 certified PCB assembly house, operates under strict standards and procedures of IPC-A-610 Class 2 and IPC-A-610 Class 3, providing services of PCB assembly and PCBA functional test for customers all over the world.

Armed with 3 high speed SMT production lines with Samsung & Yamaha high-speed smt machines, place machine, reflow oven, wave soldering machine, X-RAY, AOI testing machine.And one through hole assembly lines and the most professional technical personnel.Whether you require assembly, partial turn-key assembly, or full turn-key assembly our team will produce the PCB that suite your needs in no time at all.

PCB assembly services typically involve several stages, including component procurement, PCB fabrication, solder paste application, pick-and-place components, reflow soldering or wave soldering, and final testing and inspection of the assembled PCB.

Our Advantages

Process Capacity

- Can mount 0201, 01005, QFN, BGA, CSP etc.

Process Capacity

- Can mount 0201, 01005, QFN, BGA, CSP etc.

Capabilities

| Capability | Parameter |

|---|---|

| Assembly Types |

SMT Assembly( with AOI inspection) BGA Assembly(with X-Ray inspection) Through-Hole Assembly SMT & Through-Hole Mixed Assembly |

| Quality Inspection |

AOI Inspection X-Ray Inspection Voltage Test Chip Programming ICT Test Functional Tes |

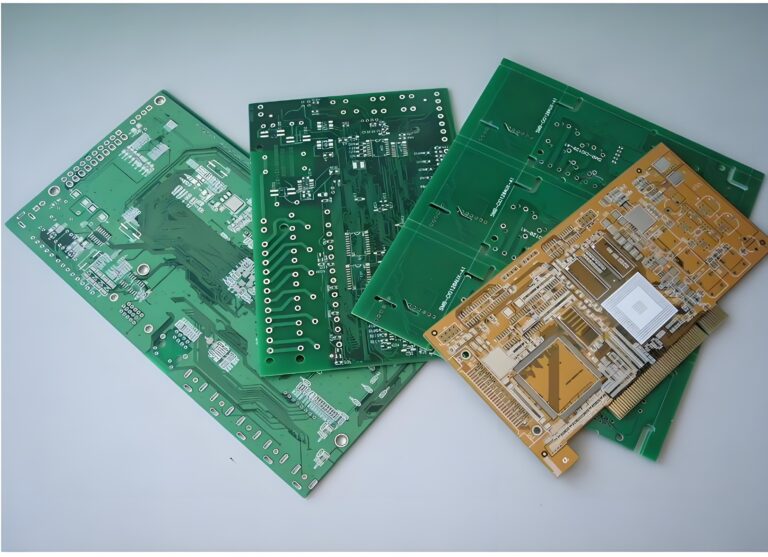

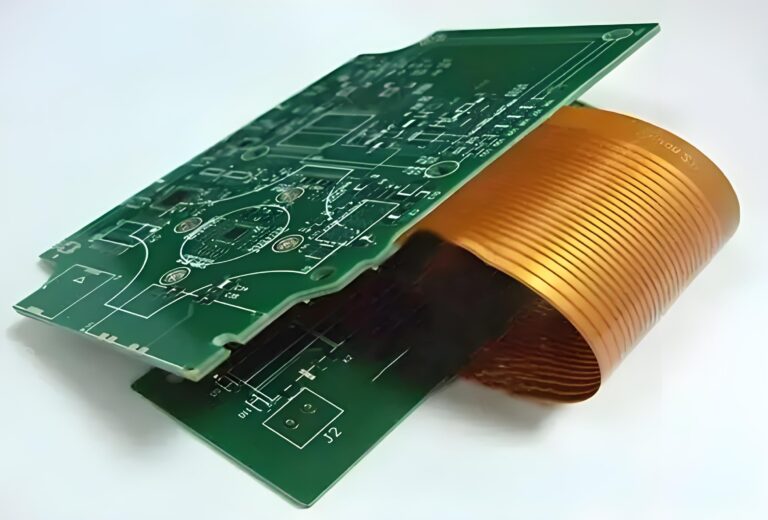

| PCB Types |

Rigid PCB Metal Core PCB Flex PCB Rigid-Flex PCB |

| Component Types |

Passives, Smallest Size 01005(inch) Fine-Pitch Chips to 0.38mm BGA (0.3mm pitch), FPGA, LGA, DFN, QFN with X-Ray testing Connectors and Terminals |

| Components Sourcing |

Full turnkey Partial Turnkey Kitted/Consigned |

| Solder Types |

Lead-Free(Rohs) |

| Files Required for Quote and Production |

Gerber RS-274X, 274D or PCB Design File BOM (Bill of Materials, xls, xlsx) Pick-N-Place File / XY File (for production only) Assembly Drawings |

| Order quantity |

5pcs to 100,000pcs From Prototypes to Mass Production |

| Assembly Lead Time | From 8 hours to 72 hours when parts are read |

Case Presentation

Operating since 2015, FAST TURN PCB has provided quick turn PCB assembly prototyping and component sourcing services for more than 100 thousand customers, and gained high praise and high-quality feedback from more than 98% of customers.

Production Environment & Equipment

High-Speed SMT Machines

Tin Paste Printing Machine

Nitrogen Reflow Soldering Oven

SPI Paste Inspection

X-RAY

Visual Inspection

Put your parts into production today

All information and uploads are secure and confidential.

FAQ

The quality inspection process in PCBA production includes multiple aspects, such as SPI (solder paste inspection) for quality inspection of printed solder paste, AOI (automatic optical inspection) for defect detection of soldered circuit boards, ICT (online testing) for testing probes to contact the test points of the PCB layout to detect open circuits, short circuits, and the soldering status of all parts of the PCBA, FCT (functional testing) for providing a simulated operating environment for the test target board to verify its functionality, and aging test racks for long-term simulated user testing of the PCBA board.

These testing steps together constitute the quality control system in PCBA production.

The positional deviation of components usually occurs in surface mount technology (SMT), which may lead to functional failure or short circuit of the circuit board.

The methods to solve this problem include ensuring accurate calibration of the SMT machine, regular equipment maintenance and adjustment, optimizing the printing process of solder paste, and ensuring uniform coating of solder paste.

In addition, automatic optical inspection (AOI) and other equipment can be used to promptly detect and correct component position deviations.

The key to optimizing welding quality lies in controlling welding temperature and time, using appropriate amounts of solder, and optimizing PCB design to ensure appropriate spacing and size of solder joints.

In addition, welding equipment should be regularly inspected and calibrated to ensure that it is in optimal working condition.

Yes, you can provide the components in a tray or bag that is clearly marked with the part numbers from your BOM.

But, please take care to protect the components during transit.

Please contact us to understand how the components can be supplied.

A turnkey order refers to a service where we take care of the entire PCB assembly process for the customer. This includes sourcing and procuring all the necessary components, manufacturing the circuit boards, performing the assembly, conducting testing and inspection, and finally delivering the finished product to the customer. We offer two types of turnkey assembly services:

Full Turnkey: We handle everything from start to finish. We procure all the required parts, assemble the PCBs, perform thorough testing and inspection, and ship the completed product directly to your designated location.

Partial Turnkey: In this option, you provide us with the necessary circuit boards and components, and we take care of the assembly, testing, and inspection. Once the PCBs are ready, we ship them to you.

These turnkey services provide a convenient and comprehensive solution, ensuring a smooth and efficient PCB assembly process for our customers.

1. Gerber files that include top and bottom silkscreen and solder paste layers.

2. The Centroid data file which contains rotations, component locations, and reference designators.

3. BOM (.xls) with vendor names, quantities, reference designators, part and package descriptions, and quantities.

4. Types of components, including SMT, through-hole, fine pitch, BGA, and more.

5. Any additional instructions and requirements.

These documents and files are essential to ensure a smooth process for turnkey assembly.

Our component engineers will provide suggestions on alternative component models and provide corresponding datasheets to customers for confirmation. The final decision is in your hands.

Please specify the PCB requirements such as layers, material type, quantity needed, and any other special capabilities. Provide your target budget and expected production timeline if possible. Including these details allows us to cater the quote to your needs.