The difference between high-speed PCB and ordinary PCB

The main differences between high-speed PCBs (printed circuit boards) and ordinary PCBs are reflected in multiple aspects such as design goals, signal transmission performance, material selection, manufacturing processes, and application scenarios.

Preparation work before mass production of PCBA

Preparation work is crucial before mass production of PCBA, including circuit board design and verification, component procurement and confirmation, circuit board production process preparation, SMT process documents and production files, circuit board sample inspection and verification, etc.

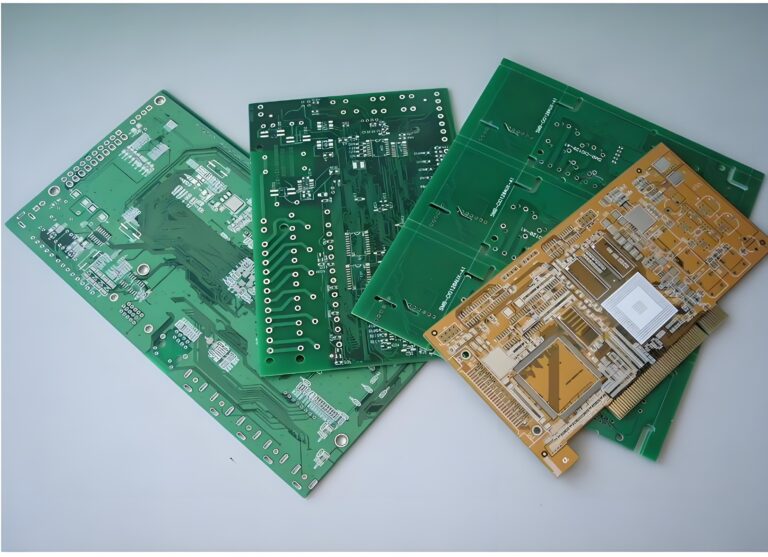

Prototype PCB Board-Fast Turn PCB

In the PCB market, the Fast Turn PCB is now creating a buzz as a leading high-tech company in Prototype PCB Board. Its Research and Development (R&D) team had an intensified twenty-one years of experience in developing a high-end prototype PCB Board.

Circuit Board Manufacturing

There is an intertwined relation between PCB assembly and circuit board manufacturing. In this light, we will be tackling PCB assembly in line with circuit board manufacturing. Prior to PCB assembly, several preparatory measures are being considered for the circuit board manufacturers to make the proper assessment of the functionality of the PCB design and have a DFM check.

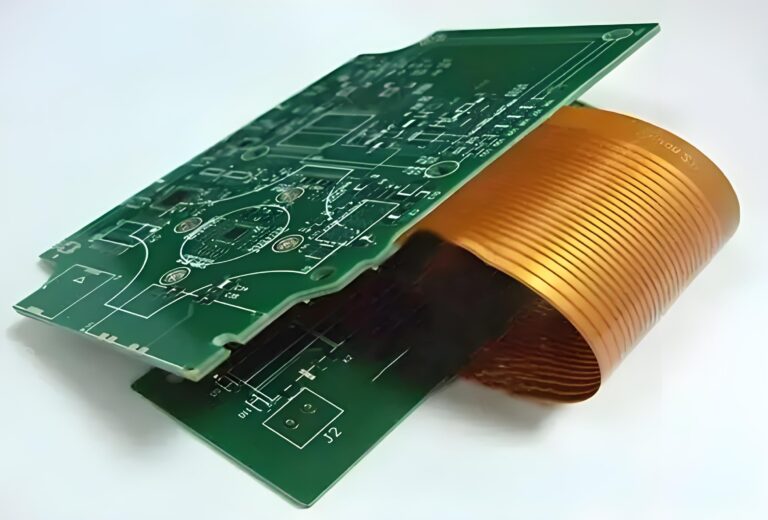

Unraveling the Advancements and Versatility of Flex PCBs

In the bustling world of electronics, the demand for miniaturized and versatile components continues to rise. An ingenious innovation stands at the heart of this modern revolution, the Flexible Printed Circuit Board or Flex PCB. Characterized by its thin profile and malleability, this versatile technology has taken the electronics industry by storm, proving integral in various applications, from medical devices to consumer electronics and aerospace systems.

Storage conditions for PCB circuit boards

Proper storage is crucial for the quality and reliability of PCBs. Temperature and humidity control, anti-static measures, appropriate storage methods, and regular inspections can effectively extend the service life of PCBs.

Reasonable storage not only helps improve the reliability of products, but also provides a solid guarantee for subsequent production and assembly.

What is the difference between PCBA processing and SMT processing?

PCBA processing is the process of assembling printed ci […]

SMT point calculation quotation

In SMT chip placement processing, calculating the number of points and quoting is crucial, involving factors such as the quantity, type, board, and order quantity of components. Accurate accounting, rational design, long-term cooperation, and flexible adjustment of orders can optimize quotations, control costs, and improve procurement efficiency.

What are the commonly used SMT programming software

In SMT (Surface Mount Technology) programming, there are various commonly used software with different characteristics and functions. The following are some of the main SMT programming software:

What industries are suitable for small batch SMT surface mount processing?

In today’s rapidly developing electronic manufacturing industry, small batch SMT surface mount processing services are gradually becoming a favored choice for many industries. This service model is not only flexible and efficient, but also effectively reduces production costs and risks, making it particularly suitable for industries with customized and diversified needs for electronic products.

Below, we will discuss in detail which industries are suitable for small batch SMT surface mount processing services.

Analysis of SMT Process Flow

SMT (Surface Mount Technology) is an efficient and precise electronic component assembly technique widely used in modern electronic manufacturing.It achieves high integration, compact size, and lightweight electronic products by precisely mounting surface mount components on a printed circuit board (PCB) and connecting them through soldering.

Seven core advantages of PCBA one-stop service

PCBA one-stop service refers to entrusting the entire PCBA process, including design, procurement, processing, testing, etc., to a professional PCBA manufacturer. This approach has significant advantages in simplifying processes, reducing costs, ensuring quality, providing one-stop services, optimizing management, flexible production, and technological innovation