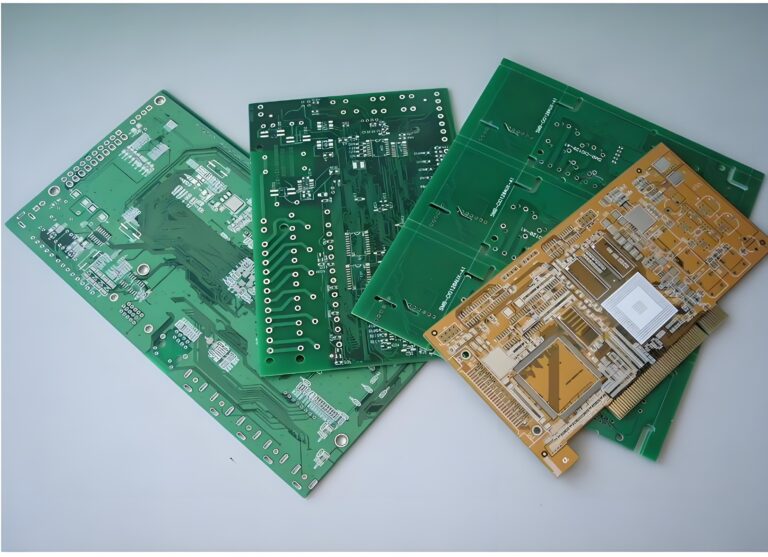

PCBA one-stop service refers to entrusting the entire PCBA process, including design, procurement, processing, testing, etc., to a professional PCBA manufacturer. This approach has significant advantages in simplifying processes, reducing costs, ensuring quality, providing one-stop services, optimizing management, flexible production, and technological innovation.

Simplify the customer procurement process

Simplify the customer procurement process: Traditional PCBA processing services require customers to purchase materials, manage inventory, and coordinate cooperation among multiple suppliers on their own. The one-stop service entrusts all material procurement and processing tasks to the PCBA factory, and customers only need to provide product design drawings and technical requirements, greatly simplifying the procurement process and reducing customer management pressure.

Reduce inventory costs

Reduce inventory costs: In the one-stop service model, PCBA factories are responsible for material procurement and inventory management, and customers do not need to bear a large amount of inventory costs, avoiding capital occupation caused by inventory backlog and effectively reducing financial pressure.

Ensure product quality and delivery time

Ensure product quality and delivery time: As PCBA factories integrate their own supply chain resources, they are responsible for material procurement, production planning, and product processing and testing, which enables them to better control product quality and delivery time, ensuring product stability and reliability.

One stop service

One stop service: PCBA one-stop service eliminates the need to spend a lot of time searching for suppliers for small batch orders. For suppliers with small quantities who are unwilling to spend more time and manpower costs, the PCBA one-stop factory model can combine several small orders into a large batch, easily meeting any order quantity.

Optimize supply chain management

Optimize supply chain management: One stop service transfers the responsibility of supply chain management to the PCBA factory, improves the operational efficiency of the supply chain, reduces costs and risks by integrating supply chain resources and optimizing material management systems.

Flexibility

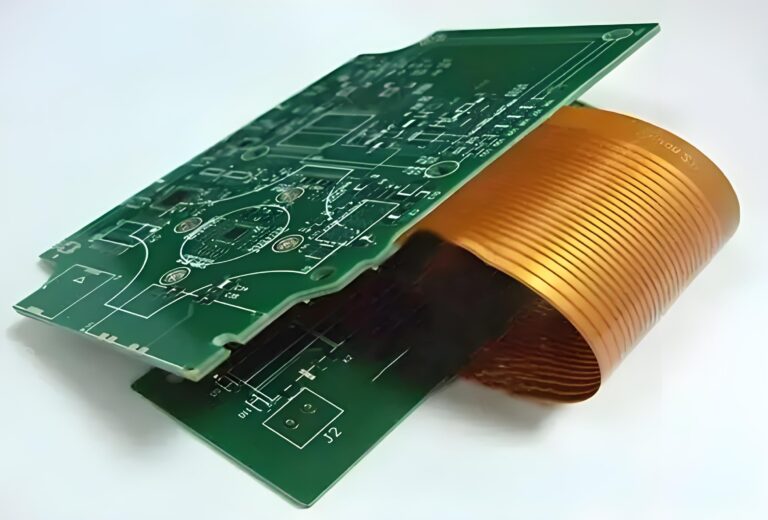

Flexibility: For small businesses, the PCBA one-stop model is very suitable. Small start-up enterprises may not have mature product design and market research, and may not be certain of the required quantity, so they can only conduct small-scale trial production. At the same time, small companies do not have as well-equipped personnel and require more flexibility in one-stop services.

Technological innovation and automation application

Technological innovation and automation application: With the continuous development and innovation of electronic manufacturing technology, PCBA factories can use automation and intelligent technology to improve production efficiency and product quality, providing customers with more efficient and accurate services.