Your PCB And PCBA Turnkey Service Provider

We are a PCB and PCBA service provider over 15 years.

<br> We are growing with our clients together.

FAST TURN PCB was established in 2015. We own a PCB factory and a PCB assembly factory, employing approximately 350 staff. We focus on providing turnkey solutions for PCB and PCBA, excelling in small and medium-sized volume production and ensuring quick delivery. 70% of our products are sold to Europe and America, 30% are sold to Other market. They are widely utilized in medical devices, industrial control, telecom communication and semiconductors.

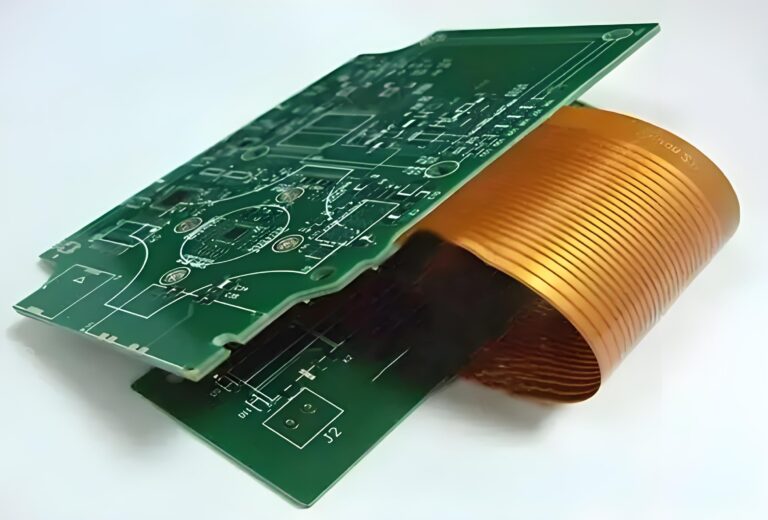

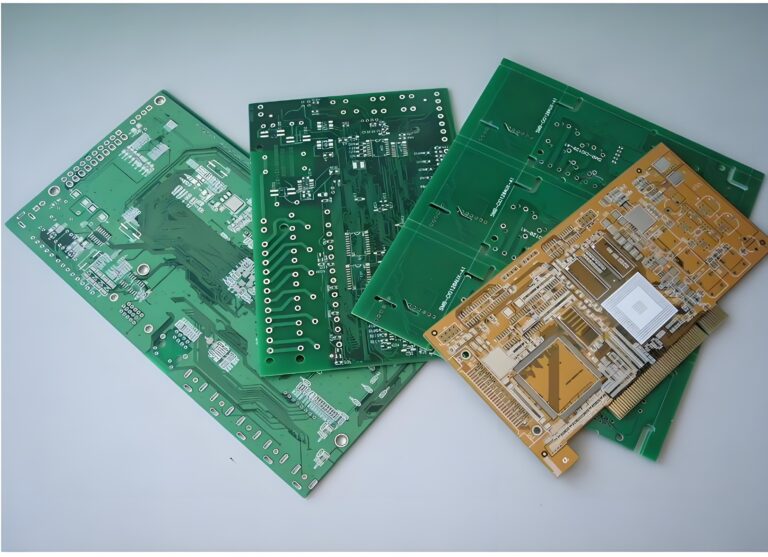

Our PCB factory is Good at multi-layer PCB (4-50 layers), HDI blind and buried boards, high-frequency boards and rigid-flex boards. It is certified by ISO 9001, ISO13485, QJB, UL, ROHS and REACH. Each PCB board undergoes 100% inner and outer layer AOI, E-test, and via hole wall test, and so on.

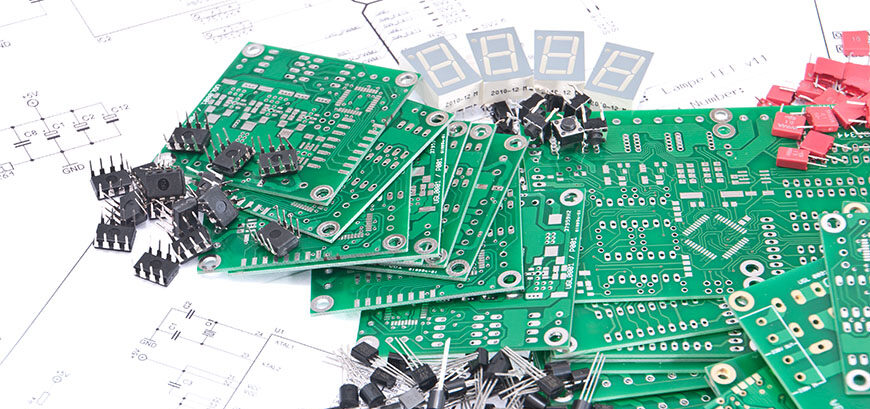

Our SMT factory has the capacity to handle BGA, QFN, CSP, LGA, 0201, 01005. and some testing .

Our goal is to provide “Reliable Quality, Quick Delivery, Professional Service, and Fair Pricing”.

Reliable PCB Turnkey Solution Provider

Below is the list of detailed descriptions of services we provide for you.

PCB FAB

High multi-layer (4-50 layers), HDI, rigid-flex boards, semiconductor test boards, etc.

BOM Procurement

Have a stable and reliable component supply chain.

LEARN MORE ->

Testing

Functional test, Burn-in, ICT test, Testing jig, etc.

LEARN MORE ->

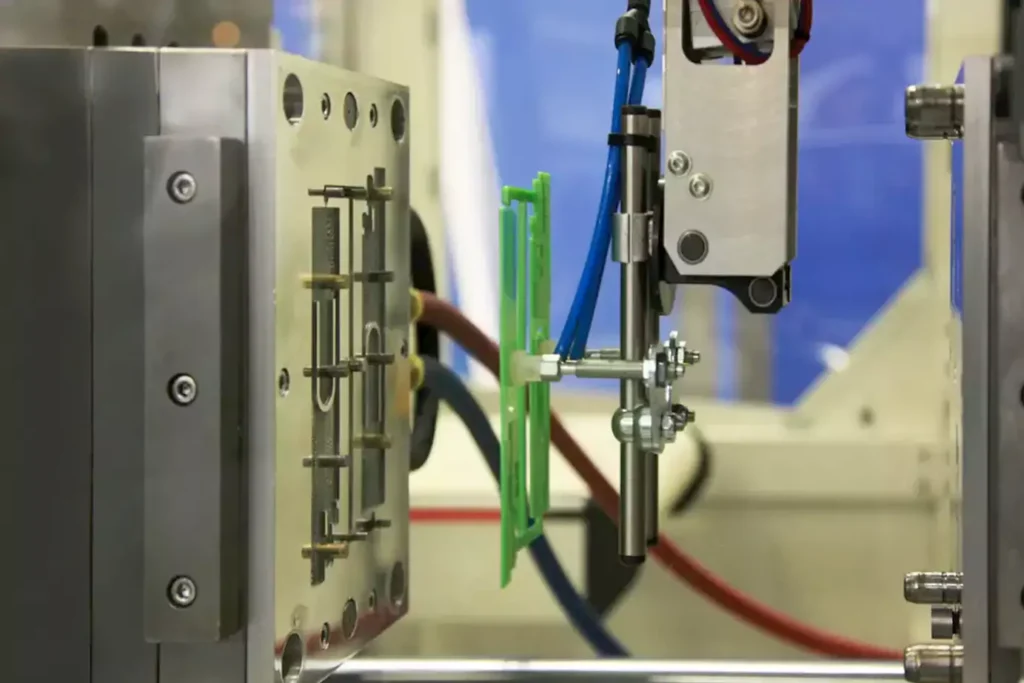

Value-Added Services

Mould, Plastic Injection and Cables, etc.

LEARN MORE ->

View All Services

LEARN MORE ->

Featured Cases

With over 10 years of experience, we specialize in one-stop PCB and PCBA manufacturing, delivering high-quality solutions with precision and efficiency.

At Fast Turn, we continuously innovate to meet industry demands, ensuring fast turnaround and reliable performance. Each case showcases our strength and commitment to excellence.

Why you can trust Fast Turn?

Fast Turn PCB focus on providing turnkey solutions for PCB and PCBA, excelling in small and medium-sized volume production and ensuring quick delivery.

Quality Assurance System

- Full-process three-level quality control management (IQC/IPQC/OQC)

- Use original materials authorized by international manufacturers

- Pass ISO 9001 , 13485 ,UL and Rohs certification

Cost optimization plan

- Bulk purchase of source materials to save costs

- Our own factory is more cost-effective

- Fully automatic SMT production line reduces costs and increases efficiency

Flexible production capacity

- Support 72-hour rapid proofing

- Flexible delivery times and individual requirement to be satisfy

- Compatible with small batch trial production and medium-level orders

- Full technical escort by the engineering team

Customer value proposition

- Exclusive project manager 1V1 service

- 24-hour online technical support

- Full life cycle quality traceability

A customer’s words mean more than ourssee what our satisfied customers have said about how we fulfilled their requirements.

JS

Les Komarck

- US

Great news Well done, it was fast turn indeed.

Great news.Well done,it was fast turn indeed.Your ability to maintain such high standards while delivering ahead of schedule is greatly appreciated. This timely completion has already made a positive impact,Many thanks again for your excellent work.Let’s schedule a call next week to discuss the next phase.

Date of experience:April 07, 2024

JS

Gio

- CA

Completely satisfied with your service and PCBs.

I’m truly delighted with the PCB manufacturing service provided by your company! I checked the PCBs in my design,all specifications meet my requirements perfectly,

I’m completely satisfied with your service and PCBs.

I rate your products and services a perfect 5/5 stars. Thank you for helping bring my electronic designs to life!

Date of experience:May 1, 2024

JS

Edwin

- UK

Good package with service, price, quality and delivery time.

Tracking number received, Fastturn do a good job!

In the moment I see a good package with service, price, quality and delivery time at

Fastturn, Excels in packaging craftsmanship, service professionalism, cost-effectiveness, product quality, and punctual delivery.Hopefully this will last the next years. Regards.

Date of experience: April 07, 2023

JS

Glenn

- US

Reliable company, outstanding in precision work.

This is tremendous news! Many thanks to you and your team for your dedication and hard work – it’s very impressive. I genuinely appreciate your tireless efforts to help us achieve our goals, continuing our productive partnership in future endeavors. Warmest regards and sincere appreciation for making this achievement possible.

Date of experience:December 13, 2024

JS

Duy Nguyen

- ISR

We are quire satisfy with your services,thanks.

We received your PCB shipped from Fastturn.We are satisfied with your services. There are no issues with delivery time, circuit board appearance, or packaging.Our team are doing some extra test before making conclusion.Anyway, thank so much for your effort to support us,looking forward to next collaboration. Best regards

Date of experience:March 02, 2024

JS

John S

- SG

We will recommend your company definitely to others.

A pleasant collaboration can be given a score of five

communication: 5 out of 5. Very good communication skills,

leading time: 5 out of 5. The manufacturing time of the PCBs

quality: 5 out of 5. PCB and PCBA quality meets our requirements.

Overall process: 5 out of 5.We will recommend your company definitely to others.

Date of experience:November 09, 2024

JS

John S

- US

Reliable company, outstanding in precision work.

It’s very nice that you can make complex miniature prototypes down to the smallest details and with also a high precision. For us, this quality is necessary to do reliable tests. Great that you can meet these high requirements. Good work, keep it up!

Stay affordable and we hope to continue working with you for a long time.

Date of experience: April 07, 2023

JS

John S

- US

Reliable company, outstanding in precision work.

It’s very nice that you can make complex miniature prototypes down to the smallest details and with also a high precision. For us, this quality is necessary to do reliable tests. Great that you can meet these high requirements. Good work, keep it up!

Stay affordable and we hope to continue working with you for a long time.

Date of experience: April 07, 2023

Our Factory

Two high-speed placement lines, one wave soldering line and one finished product assembly line.

Latest News & Article

The difference between high-speed PCB and ordinary PCB

The main differences between high-speed PCBs (printed circuit boards) and ordinary PCBs are reflected in multiple aspects such as design

Preparation work before mass production of PCBA

Preparation work is crucial before mass production of PCBA, including circuit board design and verification, component procurement and confirmation, circuit

Prototype PCB Board-Fast Turn PCB

In the PCB market, the Fast Turn PCB is now creating a buzz as a leading high-tech company in Prototype

Circuit Board Manufacturing

There is an intertwined relation between PCB assembly and circuit board manufacturing. In this light, we will be tackling PCB

Put your parts into production today

All information and uploads are secure and confidential.