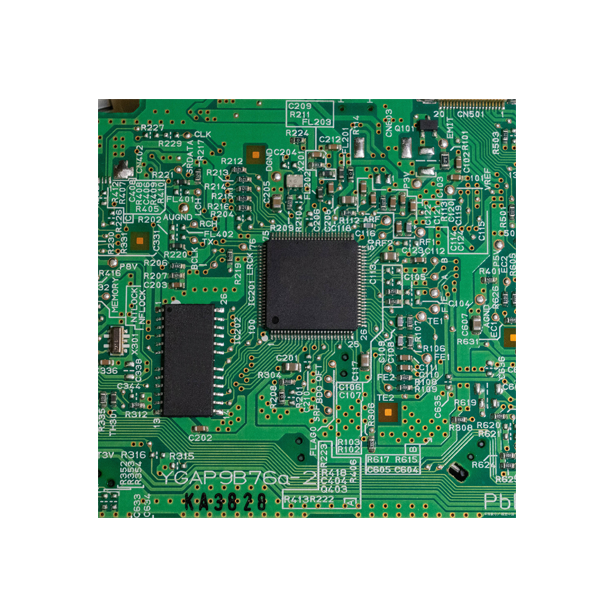

Mass PCB Assembly

Mass PCB Assembly refers to the assembly of thousands of electronic components onto PCBs at extremely high speed and precision on highly automated production lines,.

Highly automated: Advanced automation equipment and intelligent management systems are adopted.

High precision requirements: There are extremely high demands on the placement position, angle, pressure, etc.

Mass production: achieving efficient and low-cost mass production by optimizing production processes and adopting parallel processing technology.

Strict quality control: Implement a comprehensive quality management system.

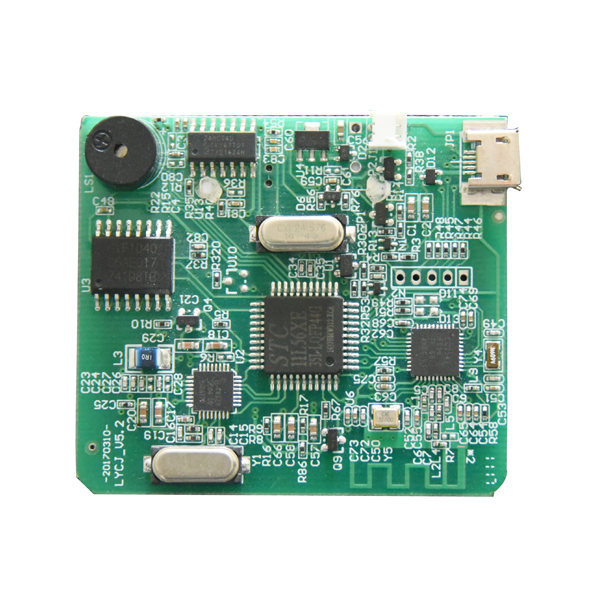

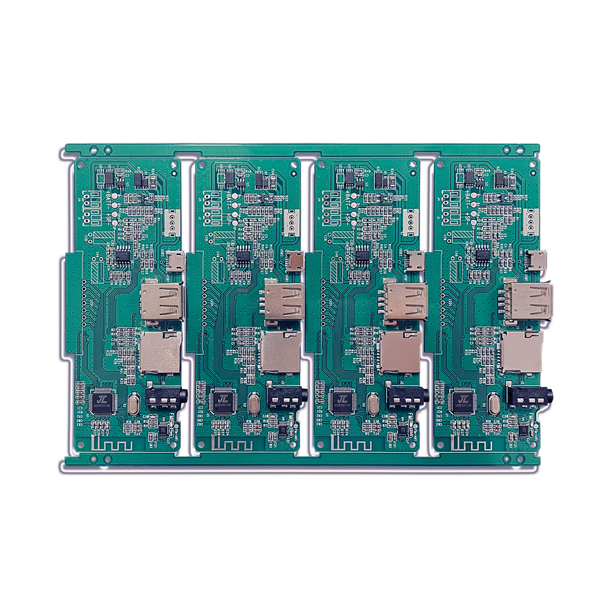

Product Showcase

Capabilities

| Capability | Parameter |

|---|---|

| Assembly Types | SMT Assembly( with AOI inspection) BGA Assembly(with X-Ray inspection) Through-hole Assembly SMT & Through-hole Mixed Assembly Kit Assembly |

| Quality Inspection | AOI Inspection X-Ray Inspection Voltage Test Chip Programming ICT Test Functional Test |

| PCB Types | Rigid PCB Metal core PCB Flex PCB Rigid-Flex PCB |

| Component Types | Passives, Smallest Size 0201(inch) Fine-Pitch Chips to 0.38mm BGA (0.3mm pitch), FPGA, LGA, DFN, QFN with X-Ray testing Connectors and terminals |

| Components Sourcing | Full turnkey Partial turnkey Kitted/Consigned |

| Solder Types | Lead-Free(Rohs) |

| Files Required for Quote and Production | Gerber RS-274X, 274D, or PCB Design File BOM (Bill of Materials, xls, xlsx) Pick-N-Place File / XY File (for production only) Assembly Drawings |

| Order quantity | 5pcs to 100,000pcs From Prototypes to Mass Production |

| Assembly Lead Time | From 8 Hours to 72 hours when parts are ready |

Are you looking for a high-quality and full-range PCB fabrication, PCB assembly?

FAQ

The main advantages include reducing costs, improving production efficiency, ensuring consistency and reliability of product quality, and responding quickly to market demand.

Advanced automatic surface mount machines are usually used to ensure precise placement of components through high-precision machine vision systems and precise mechanical control.

Production defects are usually detected through online inspection equipment and offline sampling. Once defects are found, they will be immediately marked, isolated, and repaired, and if necessary, the production source will be traced for improvement.

Methods to improve production efficiency include optimizing production processes, adopting parallel processing technology, increasing equipment utilization, and reducing production interruptions.

Managing a complex supply chain requires establishing an effective supplier management system, including supplier evaluation, order management, inventory management, logistics tracking, etc., to ensure timely supply of components and cost control.