Turnkey PCB Assembly

Turnkey PCB Assembly is a comprehensive electronic manufacturing solution that covers the entire process from raw material procurement, PCB design and manufacturing, component placement, welding, testing to finished product assembly and packaging.

This service model aims to provide customers with a convenient, efficient, and high-quality electronic product manufacturing experience, allowing them to focus on product design and marketing strategies without worrying about tedious details in the production process.

We will be responsible for coordinating and managing the entire production chain based on the circuit design drawings and component lists provided by the customer.

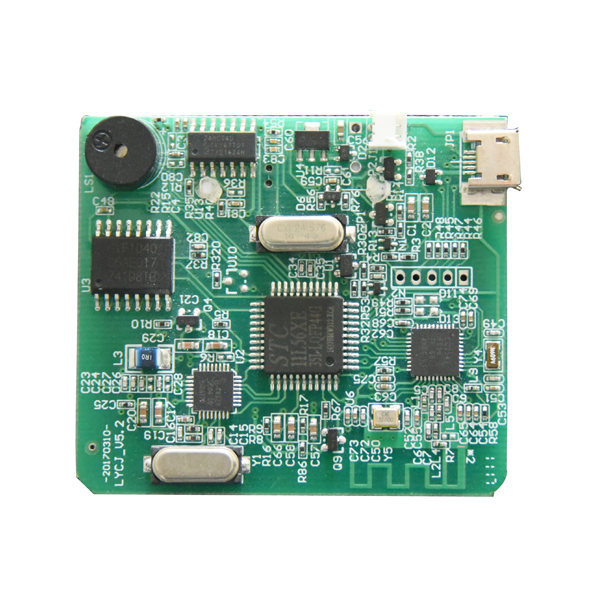

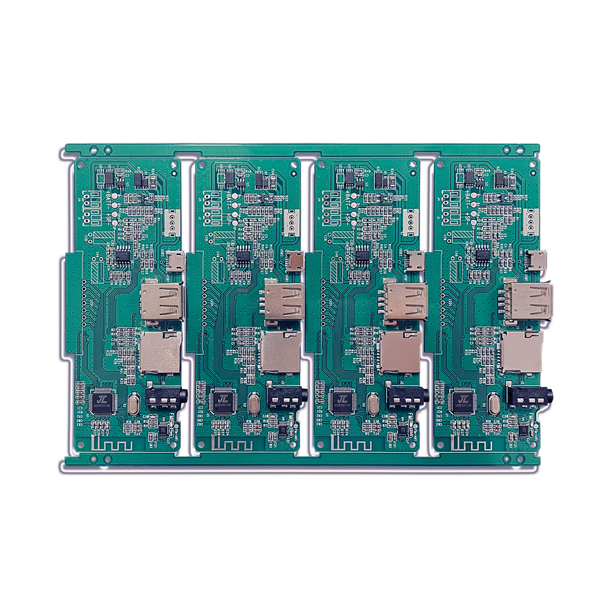

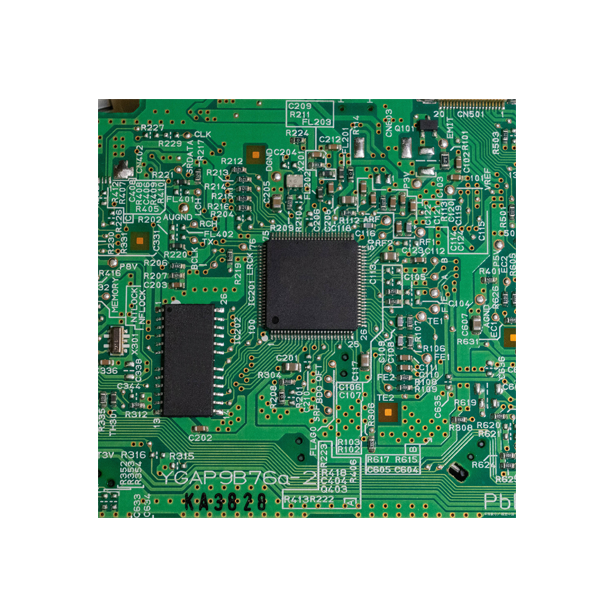

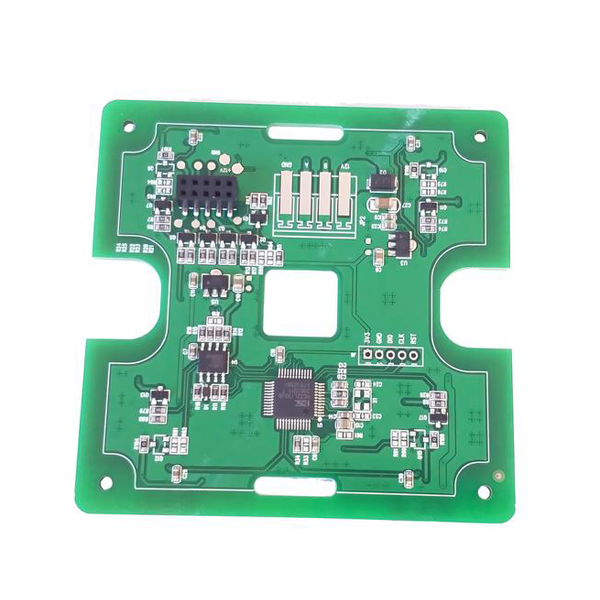

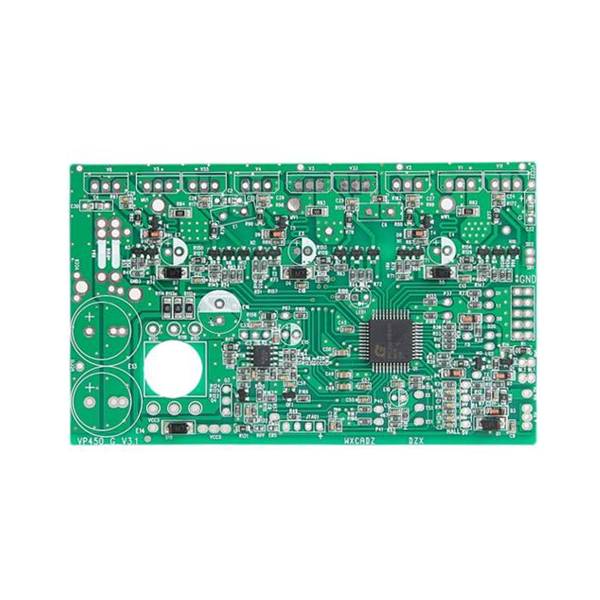

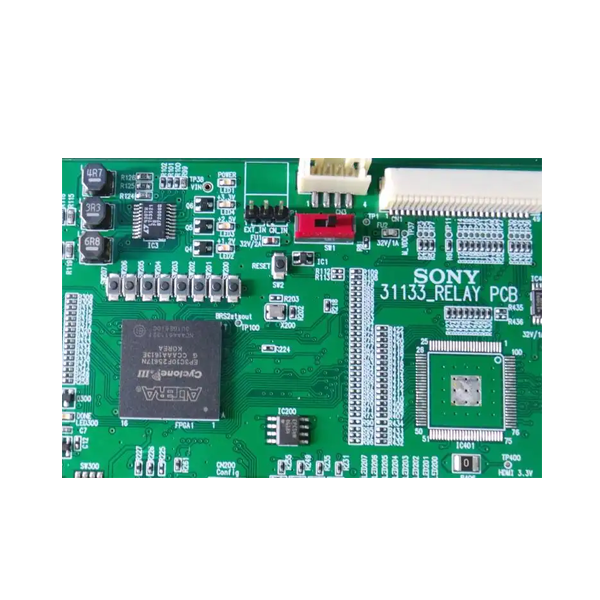

Product Showcase

Capabilities

| Capability | Parameter |

|---|---|

| Assembly Types | SMT Assembly( with AOI inspection) BGA Assembly(with X-Ray inspection) Through-hole Assembly SMT & Through-hole Mixed Assembly Kit Assembly |

| Quality Inspection | AOI Inspection X-Ray Inspection Voltage Test Chip Programming ICT Test;Functional Test |

| PCB Types | Rigid PCB Metal core PCB Flex PCB Rigid-Flex PCB |

| Component Types | Passives, Smallest Size 01005(inch) Fine-Pitch Chips to 0.38mm BGA (0.3mm pitch), FPGA, LGA, DFN, QFN with X-Ray Testing Connectors and Terminals |

| Components Sourcing | Full Turnkey Partial turnkey Kitted/Consigned |

| Solder Types | LeadedLead-Free(Rohs) |

| Files Required for Quote and Production | Gerber RS-274X, 274D, or PCB Design File BOM (Bill of Materials, xls, xlsx) Pick-N-Place file / XY File (for production only) ASSEMBLY Drawings |

| Order quantity | 5pcs to 100,000pcs From Prototypes to Mass Production |

| Assembly Lead Time | From 8 hours to 72 hours when parts are ready. |

Are you looking for a high-quality and full-range PCB fabrication, PCB assembly?

FAQ

Turnkey PCB Assembly is a comprehensive electronic manufacturing service that provides customers with a one-stop solution from design, raw material procurement, PCB manufacturing, component mounting, welding, testing, to finished product assembly and packaging.

Turnkey PCB Assembly is a comprehensive electronic manufacturing service that provides customers with a one-stop solution from design, raw material procurement, PCB manufacturing, component mounting, welding, testing, to finished product assembly and packaging.

You need to provide information such as circuit design diagrams, component lists, product specifications, and performance requirements for the service provider to carry out accurate manufacturing and assembly.

Yes, Turnkey PCB Assembly services typically support flexible production modes from small-scale trial production to large-scale production.

Prices are usually calculated based on factors such as project complexity, component costs, PCB size and quantity.

The service provider will provide a detailed quotation and negotiate with the client to determine the final price.